News & Press Releases

London, September 10, 2024

Primetals Technologies Launches the Latest in High-Definition Flatness Correction for the Rolling Industry

- Next-level rolling mill cooling spray control

- Compatible with aluminum, brass, and copper flat rolling mills and steel hot-strip mills

- Delivering exceptional product flatness at lower capital expenditures

- Designed and manufactured in the UK to the highest quality and machining tolerances

In a world where the demands for modern manufacture are ever-changing, rolling mills require the best technology to produce "flat" strip with minimal defects. The all-new Integral Solenoid Valve (ISV) Electric Compact from Primetals Technologies offers the highest definition control without the need for compressed air supply, reducing both the capital and operating costs.

Market-Leading Flatness Technology

Through 45 years of evolution, the Integral Solenoid Valve (ISV) spray system from Primetals Technologies has become the industry standard for cooling, enabling steel and aluminum mills to achieve optimal flatness. Applying zone cooling and lubrication across the width of the work rolls addresses residual flatness errors and controls the bulk temperature of the mill during the rolling process.

The new ISV Electric Compact valve pushes the technology further by increasing the flow rate control from 10 discrete cooling levels up to a possible 120 levels, all within a narrower 25-millimeters zone width – delivering true high-definition control.

Operating Principle

Each valve has its own 24V DC-driven solenoid mounted within the rear section of the valve body. By energizing and de-energizing the solenoid, an internal shuttle mounted in the front section of the valve can move back and forth to open and close the valve. In the open position, coolant passes through the inlets on the valve body to the outlet situated on the end of the valve.

Engineers at Primetals Technologies have utilized extensive computational fluid dynamics (CFD) analysis to optimize the design of the valve body and internal shuttle, ensuring class-leading flow rates through the valve.

The outlet of each valve is connected to a nozzle plate to provide coolant to the mill rolls. Nozzle configurations are specifically designed using advanced thermal modelling, optimizing the spray patterns and coolant flow rates to suit the individual requirements. The optimal thermal performance may be achieved for each application, regardless of the rolling duty or individual pass schedules.

Showcase at Aluminium 2024

This latest in flatness control technology will be available to view on the Primetals Technologies exhibition stand at Aluminium 2024 in Düsseldorf, Germany. The demonstration model combines Primetals Technologies’ Air Bearing ShapeMeter, which continuously identifies and measures deviations in metal flatness. Any flatness errors identified are communicated continuously to the mill’s active flatness control system, which sends instructions to the ISV spray system. In this way, the ISV spray system has all the information needed to apply precisely modulated coolant to targeted zones on the work rolls to correct flatness errors.

Come along to see the technology in action – October 8-10, Messe Düsseldorf, Stand 4A28 (Hall 4).

ISV Spray System from Primetals Technologies installed on an aluminium foil mill.

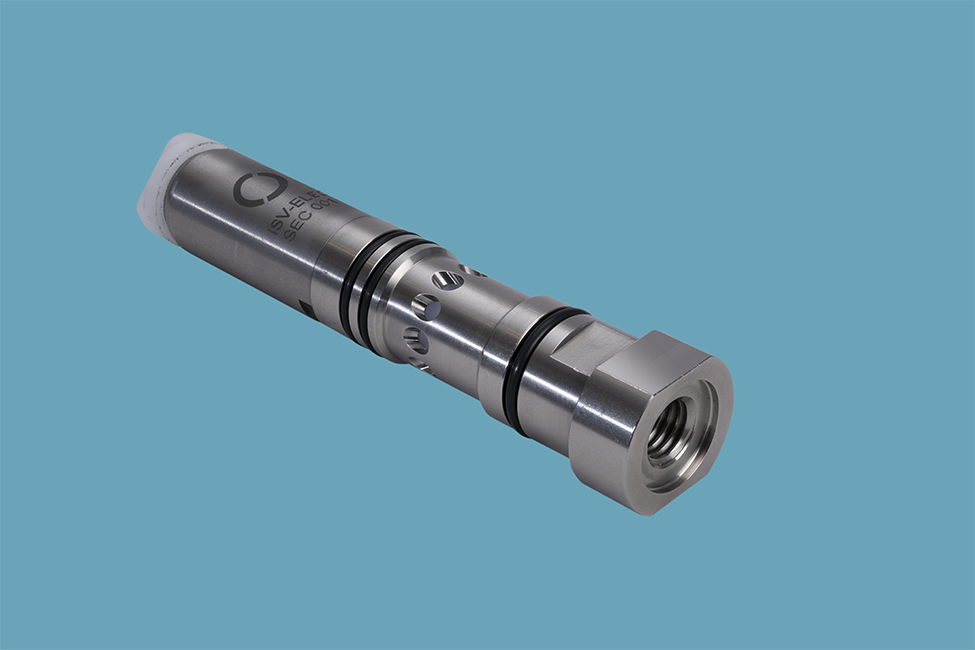

A new electric compact spray valve manufactured from stainless steel for maximum durability and corrosion resistance.

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the finished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a Group Company of Mitsubishi Heavy Industries, with around 7,000 employees worldwide. To learn more about Primetals Technologies, visit the company website www.primetals.com.