DIAGNOSTICS, MEASUREMENT & INSPECTION — CONDITION-MONITORING FOR PEAK PRODUCTIVITY

Streamlining the workflow for maximum output at lower cost

Primetals Technologies is a pioneer of advanced diagnostic systems, data analytics, and condition-monitoring systems, and works tirelessly to make the metals-production process as transparent as possible. Our mechatronics solutions for existing or new production lines represent a significant technological step forward, while our laboratories and simulation systems for chemical, physical, and mechanical testing of raw materials and end products, as well as hot metal and pig iron, help to boost productivity. Condition-monitoring systems from Primetals Technologies – which can be optimally combined with a well-executed maintenance strategy – are geared toward maintaining peak productivity and the highest product quality, while keeping operating costs to a minimum.

Advanced technologies for steelmaking

Foaming Slag Manager

The Foaming Slag Manager is an optical foaming slag detection and control system for automated carbon injection in all types of electric-arc furnace. It is designed to precisely determine the slag height inside the EAF vessel.

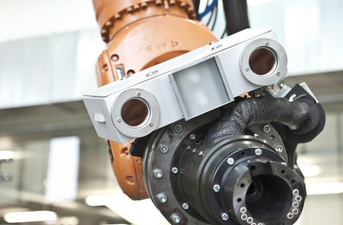

LiquiRob

The LiquiRob robotic system is designed to increase safety in the work environment and improve the accuracy of measurements in the kind of harsh conditions typical of the iron and steelmaking industry. It is ideally suited to the complex challenges of the production process.

Lomas

Lomas is a gas analysis system designed to reduce costs, increase production, guarantee the highest quality, and improve efficiency. It uses flexible analyzing sensors and patent-protected sampling devices which can be implemented in processes within the Basic Oxygen Furnace (BOF), Blast Furnace (BF), Electric Arc Furnaces (EAF), Ruhrstahl Heraeus (RH), and copper furnaces. Find out more

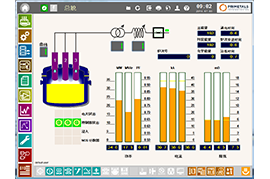

Melt Expert

Melt Expert is the next generation control system for electric arc and ladle furnaces and as the successor to Arcos and Simelt Electrode Control Systems it is the product of more than 35 years of experience. For existing customers, Primetals Technologies offers upgrade kits to convert Arcos and Simelt systems to the new technology. Building on the advantages of previous solutions, new features such as KPI, plant monitoring, customer-oriented interfaces, and sophisticated control strategies, ensure highly efficient production. Find out more

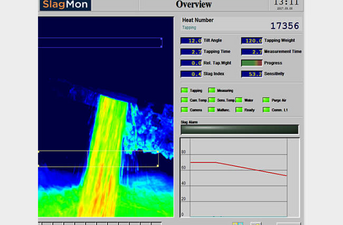

SlagMon

SlagMon is a thermographic slag identification system designed for rapid and early slag detection. It allows for real-time, permanent monitoring of the tapping stream using an infrared camera capable of differentiating between steel and slag quickly and reliably. Find out more

Smarter solutions for better casting

Primetals Technologies offers customized solutions designed to reduce operating and maintenance costs while ensuring the highest levels of quality for continuous casting.

Opal

A fully integrated optical laser measurement system that ensures the highest levels of accuracy and precision in steel plants, especially in the continuous casting strand guide system and strand guide rollers. Find out more

Mold Expert

The world’s leading mold-monitoring system, which allows plant operators to look further down the strand and gain deeper insights into the factors that influence solidification in the mold and the process itself. Find out more

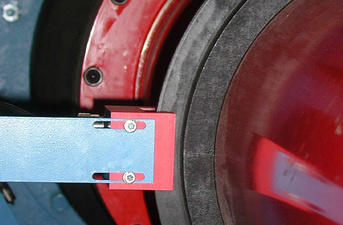

OsciMon and OsciChecker Wireless

Tools for analyzing different types of oscillator behavior of continuous casting machines and optimizing the required maintenance time. They measure oscillator movements in all three directions, and store and visualize measurement data in 3D. Find out more about OsciMon and OsciChecker Wireless

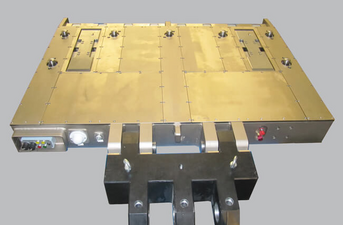

Additional measuring system for control and adjustments

Individual devices for several different mold formats and measurements can be applied in any conventional caster and adapted to specific customer needs. These robust measuring systems help operators to measure the distance between opposing rolls, the gap, alignment, rotability of rolls, and also analyze oscillator behavior. Find out more about Gap Checker, Strand Checker, Taper Checker / Taper Checker Wireless, and Mold Checker Long / slab.

Advanced rolling and processing technologies

Primetals Technologies makes sure that steel plants always have the latest technologies in place, helping producers to constantly raise quality standards and to meet growing market demand.

EdgeMon

EdgeMon is applicable for technologies such as Pickling Line (PL) and Coupled Pickling Line and Tandem Cold-Mill (PLTCM). This system enables the simultaneous inspection of the trimming process at both sides of the strip at full plant speed. Magnified images are visualized, knife breakouts are detected automatically, and warnings are issued in the event that edge quality falls short of the required quality standard. Cut-break ratio and burr are also measured. Find out more

PropertyMon

PropertyMon is suitable for metallic coating lines such as Continuous Galvanizing Line (CGL), and it is a quality monitoring system for the online detection of mechanical or magnetic properties of the steel strip. The system performs a continuous, inline, and contactless inspection over the whole strip length based on an electromagnetic measurement principle. The results are immediately available, visualized for the benefit of the operator, and stored in PropertyMon’s internal database. Find out more

ShapeMon

ShapeMon is compatible with hot rolling flat technologies such as plate mill. It is an optical sensor based on the self-radiation principle. ShapeMon is safely installed above the roller table at a height where it interferes with neither the rolling process nor the movement of the crane. When passing the field of view, the sensor automatically detects the plate and initiates the measuring procedure. Find out more

TorqueMon

TorqueMon is suitable for cold rolling and hot rolling mill stands. It is a reliable system for measuring the torque of rolling-mill shafts.Permanent, real-time measurement is based on the principle of strain gauge measurement, and sensors mounted on the rotating parts which send the measurement signals to a rotary antenna. Find out more

ChatterBlock monitoring

Avoiding strip breakage through chatter monitoring. ChatterBlock Monitoring reliably detects dangerous third octave chatter of cold rolling mill stands before it becomes audible. Find out more

Testing equipment for detailed analyses

Primetals Technologies provides laboratory solutions from studies for the development of analyses procedures to facilities integration into the metallurgical plant. Our vast technological expertise allows us to provide tailor-made laboratories for all process steps in the iron and steel industry.

- Sinter and pellets laboratories

- HBI and DRI laboratories

- Laboratories for alloys and additives

- Raw iron, steel and slag laboratories

- Macro-structure and metallographic laboratories

- Laboratories for physical and mechanical testing

- Water, gas, and oil laboratories

Primetals Technologies is a full-service provider of engineering services for the following areas:

- Sample preparation, analysis, and testing

- Sample transportation and handling

- Laboratory infrastructure

Greater transparency in steel production

Primetals Technologies offers an innovative condition-monitoring system for the metals industry that integrates information from multiple sources in order to accurately describe the condition of functions, equipment, and even entire plants.

Predictive maintenance with advanced condition monitoring

ChatterBlock Monitoring detects dangerous third-octave-mode chatter in cold rolling mill stands before it becomes audible. Line speed is then automatically reduced and the rolling mill returns to safe operation. Furthermore, the ChatterBlock Monitoring algorithms can detect fifth-octave-mode chatter and roll defects (e.g. eccentricities, flat spots) of work and backup rolls. Find out more

Want to know more? Go to Asset Life Expert (ALEX)

Reference Story: Condition-Monitoring System based on Shock-Pulse Technology

Customer

Tata Steel Limited, Jamshedpur

Type of plant

Continuous caster ladle turret

Our solution

The use of shock-pulse technology in predictive or condition-based maintenance allows even very slow rotating bearings, such as the large swivel bearings of ladle turrets, to be monitored by measuring the small shock waves that result from metal-to-metal contact and that resonate through the bearing. The system is easy to install, and monitoring can be carried out on or offline. Signal analysis allows any potential bearing problems to be diagnosed before the situation becomes critical, thereby preventing outages or even shutdowns of the ladle turret. This solution is designed to maximize bearing lifetime, to allow sufficient preparation time should a bearing need to be replaced, and to minimize the risk of unplanned shutdowns.