Motors & Drives

Innovative drive systems customized to meet the needs of your plant

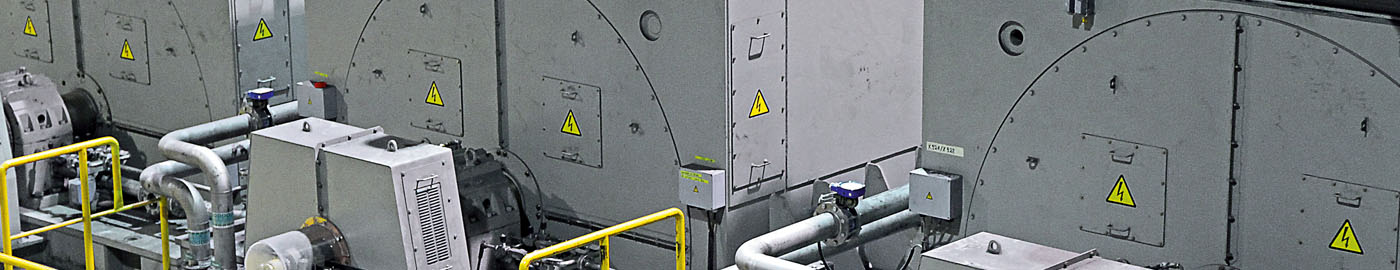

Steel plants, especially rolling mills and processing lines, depend mainly on uninterruptible processes and the quality of the steel rolled. Our drives are dimensioned per the customer's plants and metallurgical process and can be integrated seamlessly into higher-level automation systems. We deliver the complete drive system: transformers, converters, and motors – matched precisely to each other.

DECADES OF DRIVE AND MODERNIZATION EXPERTISE

Flexible solutions within a global network

Proven drive solutions

Primetals Technologies offers you the option of combining motors and drives from different suppliers. Any requested combination will be considered to save costs on the maintenance side, and your crew can work with drive systems they know well and react quickly should any issues arise.

Tailored to your needs

Motor and drive combinations are dimensioned based on their purpose. The defined product mix can be rolled with the best and most reliable motor/drive combinations selection. Thereby the customer will have the security to get the best and most future-proof drive system solution for their investment with a high potential for cost savings and earnings growth.

A global network

We provide a network of over 100 experienced drives engineers for metals applications worldwide. Therefore, we can assure fast bug-fix solutions in case of a fault and service contract solutions for all your needs.

DRIVE SOLUTIONS FOR THE METALS INDUSTRY

To support our customers with the very best drive solutions, according to steel plants, rolling mills, processing lines and metallurgical processes, we have created our own drives, starting with the VarioVerter.

VarioVerter

The VarioVerter is a cycloconverter developed by Primetals Technologies, tailored to the modernization or expansion of existing drive systems. The design of the VarioVerter aims to make the replacement or integration with existing drive systems as easy as possible.

The focus is on flexibility, with the possibility of replacing control or power sections individually or an entire system without affecting the drive footprint. Flexibility means the customer’s existing transformers and motors can remain, furthermore allowing a multi-step upgrade process that can optimize modernization costs.

MODERNIZATION AND REVAMP CONCEPTS FOR MAXIMUM DRIVE PERFORMANCE

Modernization and revamp concepts

Primetals Technologies has decades of experience in modernizing metals plants and drive systems. This is why we can guarantee that any replacement will be executed swiftly and result in equal or superior drive performance—no matter if you are replacing existing motors and DC- or Cycloconverters to the latest version of the same technology or if you are upgrading to new, state-of-the-art AC-converter technology. The expertise of Primetals Technologies assures that any such modernization project will be completed within the specified shutdown time and that the production schedule will hold.

Optimizing existing drive trains

Our experienced engineers will recalculate the existing drive train with the new pass schedules and prepare the new drive concept by reusing as much of the existing drive train as possible. We maximize potential production increases or benefits from changes to the product mix and minimize investment costs. Our customers get a single and reliable point of contact for all their needs.