News & Press Releases

London, March 20, 2025

Nippon Yakin Kogyo Produces First Coil on HZ-Mill Used for Stainless Steel Production

- Primetals Technologies has engineered and supplied the first-ever HZ-Mill for stainless steel production

- New mill replaces two monoblock cold rolling mills, enabling Nippon Yakin Kogyo to meet increasing demand for highly functional stainless steel grades

- Larger fume-exhaust system improves working conditions for operators

Japanese stainless steel producer Nippon Yakin Kogyo has successfully produced the first coil on its new HZ-Mill from Primetals Technologies. Implemented at the company’s Kawasaki plant, this reversing cold mill is the first ever HZ-Mill used for stainless steel production. Primetals Technologies was responsible for engineering, supplying key mechanical and electrical equipment, and commissioning services.

Replacing Two Monoblock Cold Mills

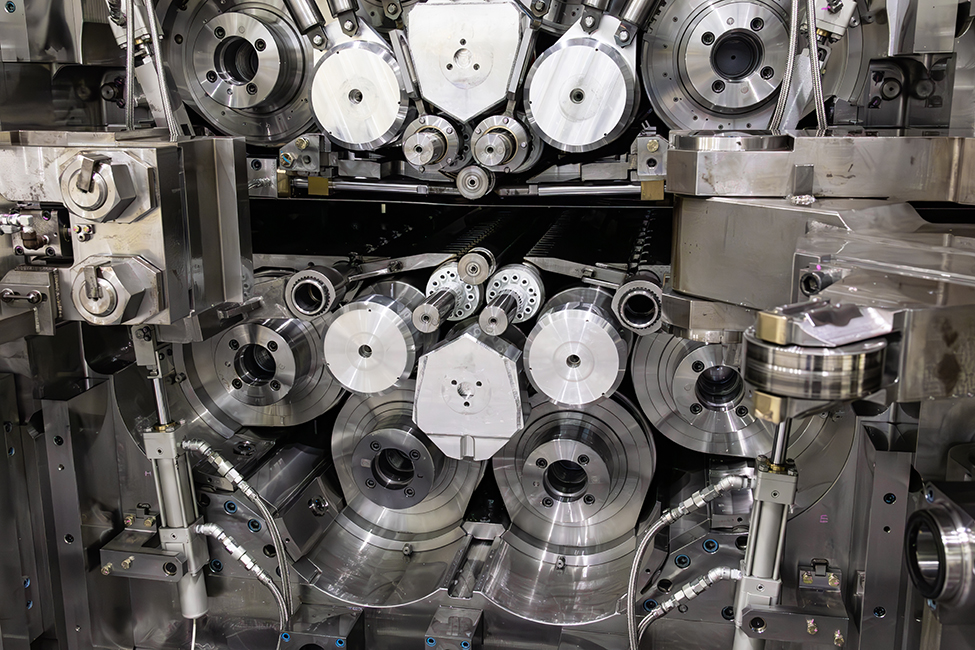

The HZ-Mill, an advanced split-housing 20-high mill from Primetals Technologies, offers several advantages over conventional 20-high mills. Designed with a large gap opening, it allows for easy strip threading and a smooth recovery after strip breakages. Additionally, the mill features a Double AS-U shape control system, ensuring a stable rolling process and improved productivity. At the Kawasaki plant, the new HZ-Mill has replaced two monoblock cold rolling mills.

Increased Production

Primetals Technologies has also installed a larger fume-exhaust system, contributing to a cleaner and safer working environment. Thanks to the HZ-Mill, Nippon Yakin Kogyo is able to increase production while reducing the thickness of highly functional stainless steel grades used in various demanding applications. The mill produces coils with thicknesses down to 0.2 millimeters and widths up to 1,350 millimeters, at a maximum rolling speed of 1,000 meters per minute.

A Leading Stainless Steel Producer

Nippon Yakin Kogyo is a leading manufacturer of high-performance materials, including nickel-alloyed flat products as well as corrosion-resistant and heat-resistant materials. The company’s product portfolio primarily includes stainless steel sheets, particularly austenitic grades. Primetals Technologies and Nippon Yakin Kogyo have collaborated on several impactful projects over the years, including the supply of a Steckel mill, a hot roughing mill, and a skin-pass mill.

Nippon Yakin Kogyo’s new split-housing HZ-Mill from Primetals Technologies replaces two monoblock cold rolling mills.

The new reversing cold mill produces coils with thicknesses down to 0.2 millimeters at rolling speeds up to 1,000 meters per minute.

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the finished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a Group Company of Mitsubishi Heavy Industries, with around 7,000 employees worldwide. To learn more about Primetals Technologies, visit the company website www.primetals.com.