News & Press Releases

London, January 13, 2025

€1.8 Million Research Grant for Sequence Impulse Hydrogen Project to Decarbonize Blast Furnaces

- New lower CO2 ironmaking technology

- Advancing the innovative Sequence Impulse Process (SIP) technology

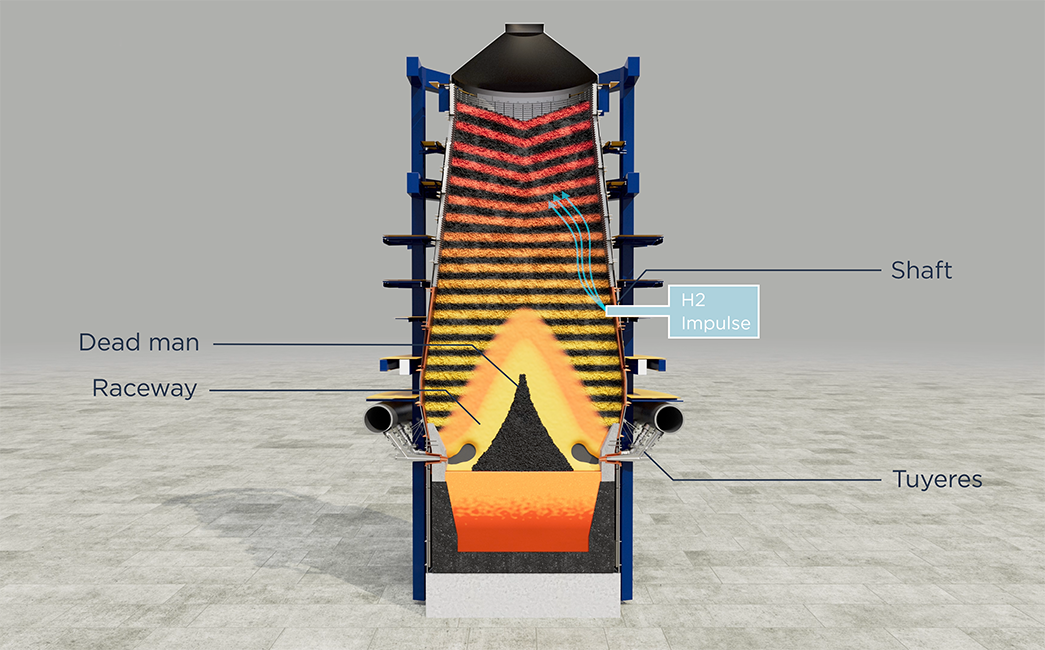

- Hydrogen pulse injection directly into the blast furnace shaft

- Driving the industry towards carbon neutrality

A research project to establish decarbonization technologies for the steelmaking industry, in which Primetals Technologies is an associated partner, has been awarded a €1.8 million research grant from the European Union (EU) via the Research Fund for Coal and Steel (RFCS). The program aims to establish a process for injecting hydrogen using the Sequence Impulse Process (SIP) technology directly into the blast furnace via the shaft. In addition to the grant, contributions will be made by each of the research partners, bringing the total project value to €3.5 million.

Driving the Green Transformation

With the iron and steel sector responsible for 7-10 percent of global CO2 emissions, commitments have already been made by the industry to achieve carbon neutrality in the next 40 years - some producers have stated even more ambitious goals. With low-CO2 production routes still at a relatively early stage, the majority of steel being produced for years to come will be via the blast furnace route. As such, it is imperative to find technologies which can lower the CO2 emissions of the blast furnace.

Hydrogen-based reduction is a much sought after solution to support decarbonization. The technology could lower emissions from the blast furnace by up to 20 percent. However, it is accompanied by significant implementation challenges when injected via the tuyeres. Building on the available and proven Sequence Impulse Process (SIP) injection technology, as already utilized on a large blast furnace at thyssenkrupp Steel Europe’s Schwelgern site in Germany, the research aims to simulate that hydrogen can be pulse-injected into the blast furnace shaft.

Industry Leading Consortium

This project, which will conclude in 2028, brings together a consortium of major European players within the iron and steelmaking sector to take the concept from laboratory to industrial demonstration. The key technology will be designed and provided by thyssenkrupp AT.PRO tec GmbH with furnace integration design and full-scale economic evaluation by Primetals Technologies Ltd. Analysis and modelling will be conducted by the research institutes VDEh-Betriebsforschungsinstitut, which also is the project coordinator, and K1-MET GmbH. thyssenkrupp Steel Europe will provide the industrial scale laboratory work fabrications and material burdening capabilities with the globally leading steel and technology group voestalpine completing the consortium as the hosts for the trial process with helium injection in the shaft to prove the simulations for gas distriution to be placed on an operating blast furnace at their Linz works, Austria.

Research Fund for Coal and Steel (RFCS)

This is an EU funding program which supports research projects in coal and steel sectors. Every year around €55 million is made available to universities, research centres, and private companies to fund projects. The funding is awarded to large clean steelmaking research and innovation breakthrough projects, aimed at leading to near zero-carbon steelmaking by 2030.

Fundings for Environmentally Friendlier Solutions

As the market leader in environmental innovations for the metals industry, Primetals Technologies is engaged in several projects for which the company has received fundings recently. These projects include solutions for hydrogen-based ironmaking.

Oxygen SIP technology installed at thyssenkrupp Steel Europe, Schwelgern – blast furnace No. 1.

Primetals Technologies and partners have received a research grant for the development of the Sequence Impulse Process (SIP) technology utilizing hydrogen in the shaft of the blast furnace.

Illustration of a blast furnace with SIP technology installed and hydrogen being injected into the shaft.

ACKNOWLEDGMENTS

The work will be carried out in the scope of the project H2II, funded by the European Union under the grant No. 101157157. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or European Research Executive Agency. Neither the European Union nor the granting authority can be held responsible for them.

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the finished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a Group Company of Mitsubishi Heavy Industries, with around 7,000 employees worldwide. To learn more about Primetals Technologies, visit the company website www.primetals.com.