News & Press Releases

London, January 29, 2025

Chinese Steel Producer Orders 6-Strand Bloom Casting Machine from Primetals Technologies

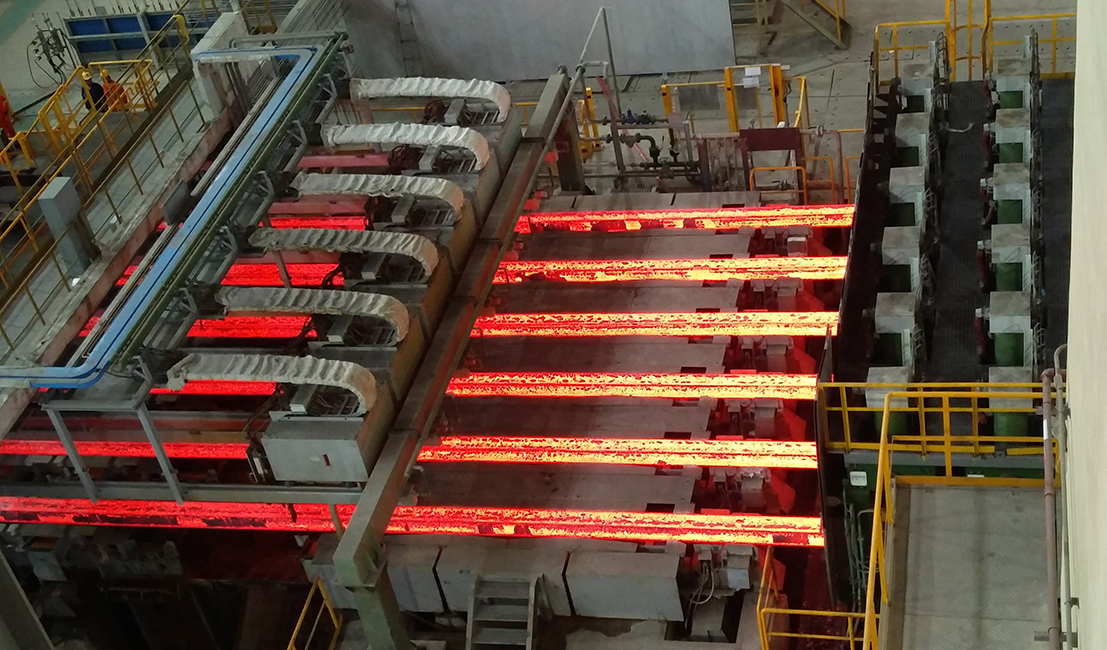

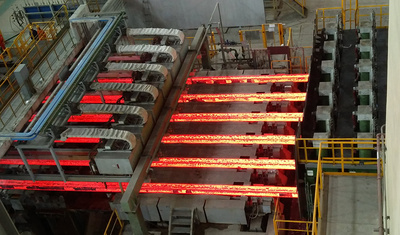

- New bloom caster to produce high-quality blooms for rail and wire rod production, including supply to the tire cord market

- Equipment to be implemented within just 12 months

A Chinese steel producer located in the northeastern part of China has placed an order with Primetals Technologies for a new 6-strand bloom casting machine. The equipment will be implemented within 2025.

Production of High-Quality Blooms

Primetals Technologies will supply the complete mechanical equipment along with full Level 1 and Level 2 automation systems. The customer’s positive experiences with long casting machines from Primetals Technologies coupled with a strong portfolio of similar references were the two main factors influencing the choice of supplier.

The caster will enable the production of high-quality blooms for export markets, focusing on premium rails and wire rod, including steel cord used for tire reinforcement. It will feature the largest curved copper tube mold ever implemented by Primetals Technologies, ensuring cost-effective production of high-value-added, high-quality thick blooms. The DynaFlex hydraulic oscillator, which allows for flexible adjustment of the mold-oscillation parameters, is another key mechanical feature, resulting in improved strand-surface quality.

State-of-the-Art Automation Solutions

Advanced automation systems make sure the casting machine is optimized for both current and future needs. The fully automated roll-gap control system DynaGap Soft Reduction minimizes centerline segregation, enhancing internal strand quality. The bloom caster will also be equipped with Dynacs 3D, a secondary-cooling model that calculates the full 3D temperature profile along the entire strand, facilitating optimal adjustments of secondary-cooling setpoints. Mold level stability will be controlled by the automatic LevCon control system, which includes autostart casting functions and auto-adaptive dynamic bulging compensation.

A Multinational Company

The producer is part of a multinational enterprise group, and the comprehensive product range includes rebar, plate, hot rolled sheet, cold rolled sheet, galvanized sheet, color coated sheet, round steel, profiled steel, wire rod, and steel rails.

Primetals Technologies will supply and implement a 6-strand bloom casting machine for high-quality production demands.

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the finished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a Group Company of Mitsubishi Heavy Industries, with around 7,000 employees worldwide. To learn more about Primetals Technologies, visit the company website www.primetals.com.