News & Press Releases

London, June 21, 2022

Brazilian customer CSP to improve safety and plant performance with new relining machine from Primetals Technologies

- New LD converter (BOF) relining machine will greatly improve safety, working conditions, and relining capacity

- Unique solution based on a detailed study

- Startup is planned for summer 2023

Recently, Brazilian steel producer Companhia Siderúrgica do Pecém (CSP) ordered a new relining machine from Primetals Technologies for its steel mill located in Pecém, a city in the state of Ceará, in north-eastern Brazil. Equipped with two 300-ton LD converters (BOFs) supplied by Primetals Technologies in 2016, CSP’s plant has an annual capacity of three million tons of slabs.

A bespoke relining machine

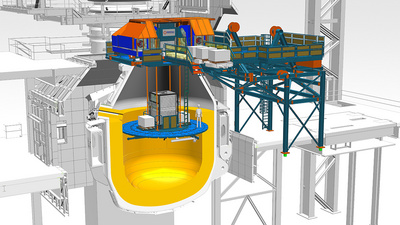

A few years ago, CSP wanted to improve the safety levels of its relining procedure and was therefore searching for a new solution. As a first step Primetals Technologies, together with CSP, did a comprehensive case study in which the limitations and issues with the existing relining procedure were analyzed and a new relining solution was developed. Comprising of a base structure, a lifting unit, a winch-suspended working platform, a combined pallet and personal elevator, and a feeding unit, the new relining machine provides access to the converter from the top, i.e. through the converter mouth. Lining material is supplied via the integrated elevator.

Patent pending procedure

The LD converters at CSP’s plant have a fixed bottom. To accommodate for this design, the new relining machine will be capable of bringing in bricks and stirring plugs for the bottom relining procedure. This patent pending process is realized by an elevator that can be unloaded both on the working platform and below. Powered by two electrical winch drives, the working platform can be placed into any relining position, as the platform diameter is adjusted to the brickwork’s contour line. The relining machine is mobile and can be used for both converters at CSP’s plant.

To ensure a smooth startup, the new machine will be manufactured, preassembled, and fully tested in Europe before being shipped to Brazil. Further testing is planned at CSP’s site to train the company’s staff.

Increased capacity

Thanks to the new solution, relining capacity will increase by about 30 percent while the shutdown time is expected to be 20 hours shorter. The main factor speeding up the relining process is the shorter cycle times, as the bricks will be transported at a faster pace. With the existing relining system, personnel working inside the vessel must stop working and stand close to the wall as brick loads are being lowered to or lifted from the converter. Furthermore, an optimized procedure is now used for relining the converter bottom and for installing the stirring plugs there, which also helps to save time.

Key facts: CSP’s new relining machine

Capacity of elevator: More than four tons

Lifting speed of elevator: 20 meters per minute

Maximum payload of working platform: Eleven tons

Lifting speed of working platform: Up to two meters per minute

Comprehensive safety concept: Overload protection, uneven load protection, redundant rope suspensions, and more.

Primetals Technologies is responsible for engineering, supply, manufacturing, startup, and advisory service for construction of the new relining machine.

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the finished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a joint venture of Mitsubishi Heavy Industries and partners, with around 7,000 employees worldwide. To learn more about Primetals Technologies, visit the company website www.primetals.com.