Endless hot rolled coils (eHRC) offer endless benefits

Endless hot rolled coils (eHRC) open up a unique range of possibilities in steel rolling that simply cannot be dismissed.

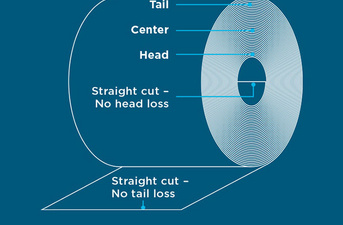

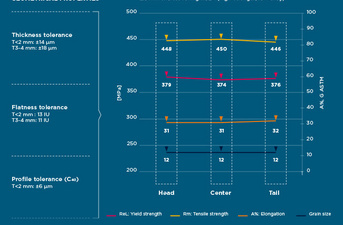

Uniform mechanical and geometrical properties from coil head to tail

What makes endless Hot Rolled Coils stand out: The endless material offers unprecedented uniformity and geometrical tolerances from coil head to tail. These factors become very important in terms of the yield for eHRC customers, as side trimming becomes obsolete and even decisive when stacking the material, e.g. for silicon steel’s application.

Request paper download: Status Achievements and Outlooks of ESP

HIGHEST SURFACE QUALITY OF HOT ROLLED COILS

The Endless Strip Production (ESP) process delivers outstanding surface quality. The clean surface after the caster, thanks to the stable mold level, is then preserved by descaling ahead of the finishing mill, oxidation prevention between mill stands, and the continuously maintained condition of the work rolls. If special grades that require ultra-high surface quality are produced, a retractable descaler can be installed in front of the high-reduction mill.

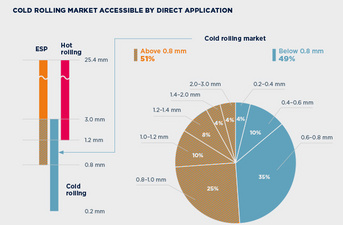

Hot rolled coils from ultra-light to heavy gauges

Arvedi Endless Strip Production (ESP) is the only process that reached 0.6 mm thickness on a hot rolled coil – this is a world record. It covers the full range from ultra-light gauges, to heavy gauges up to 25.4 millimeters (one inch).

Request paper download: Revolutionary ESP up to 20mm – precise and uniform HSLA steel

ENDLESS HOT ROLLED COILS (EHRC) CAN BE USED AS A DIRECT APPLICATION PRODUCT

Since the Endless Strip Production (ESP) process meets the end product thicknesses for a very wide range of markets, the eHRC can be used as a direct application product, competing in the cold rolled strip market with incomparably low production costs due to the reduced number of production steps (omitting cold rolling and obligatory annealing). Arvedi ESP can partially substitute cold rolling and Endless Strip Production material can also be used directly for end products.

Request paper download: Zero-carbon-emission hot rolling of direct application sheet with real ESP

EASIER COLD ROLLING AND PROCESSING

The uniform material properties of the eHRC make cold rolling and processing much easier, since there are no fluctuations within the incoming parameters. The reductions in cold rolling can be set to a minimum since the incoming eHRC gauges are smaller.

HIGHER SALES MARGINS THAN CONVENTIONAL HOT ROLLED COILS

Endless Hot Rolled Coils (eHRCs) allow for higher sales margins, compared to conventional hot rolled coils, due to the price premium for better quality and extended possibility of direct application. Additionally, downstream processors are willing to pay premium prices due to the easier processing of the uniform strip.