Arvedi Endless Strip Production guarantees lowest costs

Arvedi ESP's incomparable compact layout guarantees the lowest turnkey investment in steelmaking. During operation, ESP saves costs in energy, operational supplies, yield loss, and personnel.

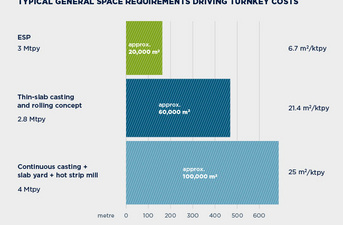

Lowest Turnkey investment in steel production

With its compact design, Endless Strip Production (ESP) saves up to 50 percent of length and, respectively, area compared to other thin-slab casting and rolling processes. Compared to conventional routes, ESP saves up to 80 percent of area in steelmaking.

Beside the fact of less land consumption, ESP reduces Capital Expenditures (CapEx) drastically, requiring

- minimum foundations

- less steel structure

- less cladding

- less roofing

- less piping

- less cabling

Request paper download: Zero-carbon-emission hot rolling of direct application sheet with real ESP

Request paper

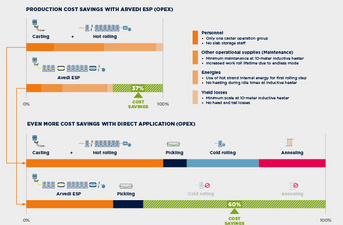

Lowest conversion costs in steel rolling

Energy is saved through the compact design, using the heat of the hot strand for the first rolling step, and by efficient inductive heating, consuming energy only when the plant is actively casting and rolling.

Operational supplies are saved by drastically reduced maintenance at the extremely short inductive heater, as well as the doubled work roll lifetime due to endless operation.

Yield is increased by avoiding head and tail losses in endless operation, and the short oxidation time in the compact layout leads to only minimum surface scale.

Personnel costs are reduced by operating only one strand and omitting slab storage operations.

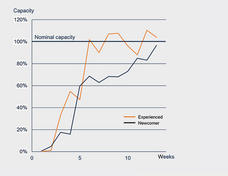

The dedicated endless production line omits the compromises of other production modes like coil-to-coil, and its numerous advantages outweigh the pretended flexibility of multiple production modes.

Arvedi Endless Strip Production (ESP) is the only process with zero greenhouse gas emissions during casting and rolling. Since 2009, Arvedi ESP lines have produced over 100 million tonnes of green steel with zero direct CO2 emissions, resulting in a total reduction of 31 million tonnes of CO2 compared to traditional casting and rolling processes.

Double the work roll lifetime in hot rolling

Arvedi Endless Strip Production (ESP) has less work roll wear as the endless process avoids shocks and damages to work rolls from slab threading. As the first rolling step happens directly to the cast strand with soft core, the strip is perfectly formed at lower forces. In the finishing mill wear-compensation work roll shifting in final mill stands doubles the work roll lifetime, compared to other processes.

Request paper download: Arvedi ESP: Reaching Maturity in Endless Casting and Rolling Technology

Endless Strip Production requires less alloying

Thermomechanical rolling of HSLA or API grades require to stay below the non-recrystallization temperature which is ensured by over-alloying. Contrary to this strategy, ESP's stable endless operation and high cooling rates by Ultra Early Power Cooling are advantageous to omitting such such over-alloying. This allows for a reduction in necessary alloying elements like Nb, Ni, Cr, or Mo.