VERTICAL CASTING — STRAIGHT TALK ABOUT A STRAIGHT SOLUTION

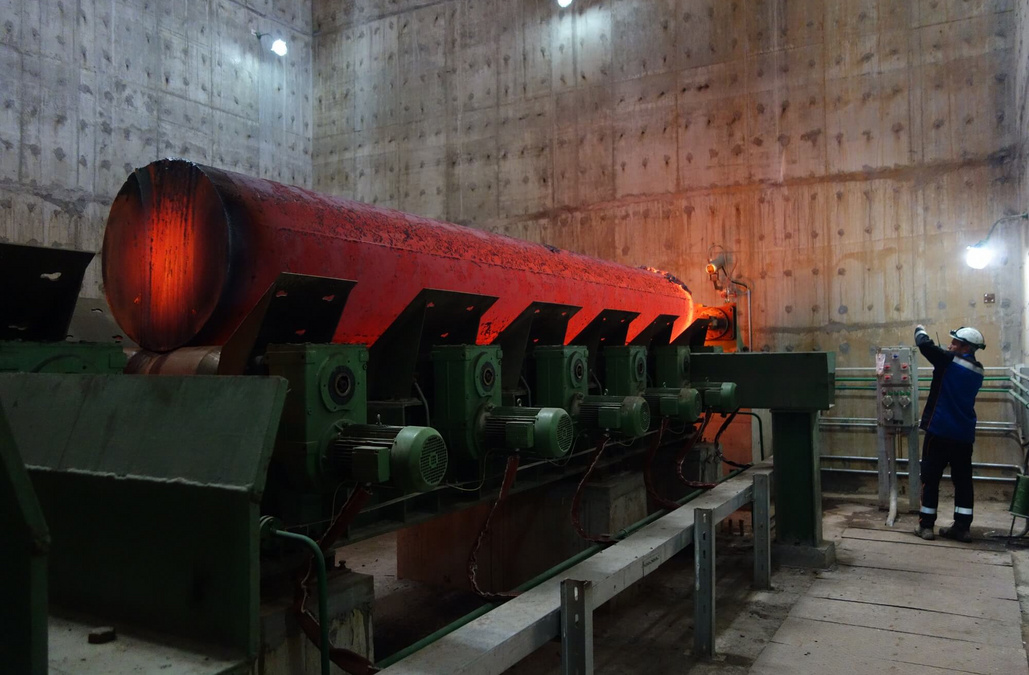

Highly specialized steel grades for the most demanding downstream applications can be produced with vertical casting machines from Primetals Technologies.

Vertical casting machines enable almost any steel grade to be cast. They are employed for the casting of steel grades that cannot be cast on a conventional bow-type caster. The advantages of vertical casters include the elimination of bending and straightening forces, optimal steel cleanliness, and a high homogeneity and symmetry of the cast slabs or blooms.

Vertical Casting

Continuous casting technology started many years ago with the vertical style-machine. The impact of this change affected a large portion of ingot steel production and resulted in considerable cost savings. Bow-type casters followed soon after and also strongly influenced cost savings and operational simplicity. The vertical caster still has its advantages with respect to product quality for very special steel grades: and for the highest quality requirements, the ingot and vertical CC route is still in use today and in certain cases is even the preferred solution. Because there are no bending and unbending procedures, there is almost no restriction in the steel grades that can be cast. In addition, the pure vertical orientation of the process allows for the best upward flotation of non-metallic inclusions and ensures the highest internal strand cleanliness. The application of the modern technological packages used today on modern bow-type casters can also extend the operational range of vertical casting solutions. As a prerequisite for optimal operation, special attention must be paid to the precise metallurgical properties used in the online systems, which are derived from the latest DynaPhase model. The latest solution for heavy-bloom round casting and the corresponding operational results are presented here to demonstrate the special features of vertical bloom casting.

Superior quality features in comparison to ingot route:

- Ideal conditions for clean steel

- Vertical design offers best conditions for floatation of inclusions to meniscus

- Non metallic inclusions are effectively captured by mold slag

- Fully symmetric microstructure, homogeneous material properties

- Electromagnetic stirring improves internal quality, optimized microstructure

- Smooth surface due to defined heat transfer conditions in the mold

- Less deformation degree of bloom

- Computer controlled operation ensures steady quality level

Want to know more? Go to Integrated Plants & Solutions

Electrics and automation for continuous casting

Sophisticated automation packages are prerequisite for state-of-the-art quality steelmaking. Primetals Technologies has always been a driver of innovation in this area, especially also providing expert technological packages and models that cover all aspects of the continuous casting process.

This capability is impressively demonstrated by recent advancements in automation solutions from Primetals Technologies that include: DynaPhase, Dynacs 3D, and DynaGap Soft Reduction 3D. This state-of-the-art suite of dynamic secondary cooling and soft-reduction packages take into account thermodynamic effects such as shrinkage and phase transitions, and thereby significantly contribute to direct quality improvements during the solidification phase in the continuous casting process.

The Mold Expert breakout predetection system increases plant availability and decreases maintenance time by prompt alarming. Thanks to its superior performance the Mold Expert system has become the world’s leading system for mold monitoring, with close to 200 installations worldwide. In addition to breakout prevention, Mold Expert provides an ever increasing number of expert packages that are used to detect possible surface defects and inform operators about challenging casting conditions.

The well proven LevCon mold level control package adapts reliably and extremely quickly to mold level fluctuations and changing casting conditions. This is made possible by advanced model-based control algorithms that can actually look into the near future to avoid disturbances in the control loop. Unsteady bulging is actively suppressed by a powerful algorithm based on modern control theory. The intelligent interaction between the advanced software and highly robust mechanical components improves safety and brings plant operators one step closer to fully automatic casting operation.

Further highlighted technological packages and process experts

- DynaWidth: Width adjustment with highest accuracy and fast speed

- Quality Expert: a milestone in improved quality supervision, quality prediction and control

- Yield Expert: cut length/weight optimization for minimized scrap and optimized yield

- Intermix Expert: precisely determination of the mixing area of two different grades on the strand

- Nozzle Expert: highest accuracy in detecting clogged nozzles and broken hoses

- Speed Expert: optimal casting speed for increased throughput and improved quality

- DynaFlex: hydraulic Oscillator for perfect surface quality

ECO Solutions for vertical casting — Saving resources, creating value

Please follow the corresponding links to learn more about our competences:

Gas Cleaning

ECO Consulting

TECHNOLOGY AND MODERNIZATION PACKAGES

Get striking results with incremental investments

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|