EXCELLENCE IN CONTINUOUS CASTING TECHNOLOGY

Primetals Technologies can refer to nearly five decades of experience in the engineering, supply, installation, start-up and commissioning of continuous casting machines. The company is therefore in an ideal position to advise and implement the optimum casting solutions for customers, both for new and existing plants.

Primetals Technologies has pioneered numerous future-oriented developments and innovations in the field of continuous casting to support producers to remain competitive. Thanks to an integrated engineering approach that covers metallurgy, mechanics, fluids as well as electrics and automation, the plants supplied are characterized by their reliability to meet the defined performance targets with regard to productivity, flexibility and product quality. Extensive prior workshop testing of equipment and systems, the installation of modular technological and mechatronic packages, as well as the application of Connect & Cast® solutions reduce project times to a minimum for both new plants and upgrades. This means short shut-down times during revamping and fast production ramp-up following plant start-ups. Producers benefit from a short return-on-investment and profitable, long-term casting operations.

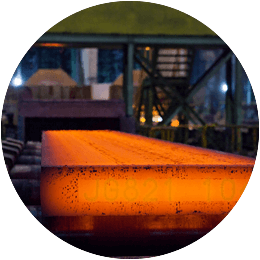

SLAB CASTING — SUPERIOR SOLUTIONS FROM THE WORLD’S LEADING SUPPLIER

As one of the original pioneers of slab-casting technology, Primetals Technologies today offers a comprehensive range of integrated equipment and system solutions to ensure high productivity, fast start-ups, short ramp-up times to full production and maximum casting flexibility.

Compact and modularly designed slab casters from Primetals Technologies, well proven in more than 400 references worldwide, are distinguished by advanced technological packages and highest-quality casting equipment and components. Individual solutions can be developed to meet specific customer requirements – from minor component upgrades to full turnkey slab caster projects. The capability to cast a wide range of steel grades, slab thicknesses and slab widths on the same casting machine allows producers to quickly adapt to changing market demands.

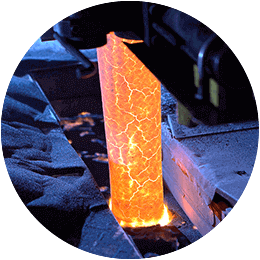

BLOOM CASTING — HIGH-PERFORMANCE, POWERFUL MACHINES TO MEET THE MARKET REQUIREMENTS

Bloom casters from Primetals Technologies are characterized by their modular design, high operational flexibility and the use of robust machine components for reliable and long-term production.

More than 100 bloom casters supplied by Primetals Technologies to date set the standards for high-performance bloom casting. In accordance with producer requirements, bloom casters are designed to comprise of smaller and lighter components that can bear high loads and stresses as well as accommodating larger bloom sections for the production of high-end products of outstanding internal quality.

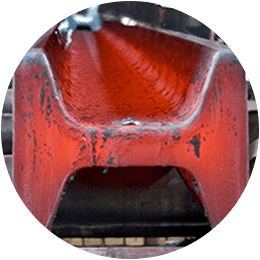

BEAM-BLANK CASTING — REDUCED ENERGY CONSUMPTION WITH NEAR-NET-SHAPE CASTING

Beam-blank casting results in fewer passes in the section mill, reduced energy use and lower production costs.

Near-net-shape casting is an energy-saving alternative to conventional bloom casting for the production of beams and sections. The greatest benefits can be derived through the direct coupling of the caster to the rolling mill. The special mold-taper design from Primetals Technologies offers a large operating window with respect to varying casting speeds and different steel grades. High-quality structural beams can be produced with a broad range of product dimensions.

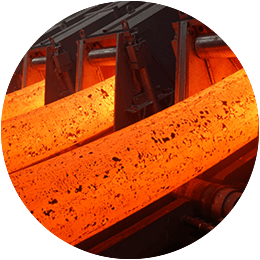

BILLET CASTING — FROM ECONOMIC CASTERS TO HIGH-SPEED SOPHISTICATED MACHINES

Compact and modularly designed billet casters from Primetals Technologies meet the requirements for the production of billet to roll to merchant bars including specialty steels for high-end applications.

Primetals Technologies casters provide more than 2,500 billet strands worldwide. On the basis of this wealth of experience, a full range of caster solutions is available that extend from standard, highly economical machines up to high-tech casters equipped with an array of advanced solutions to meet the demands for maximum productivity, operational flexibility and highest product quality.

VERTICAL CASTING — STRAIGHT TALK ABOUT A STRAIGHT SOLUTION

Highly specialized steel grades for the most demanding downstream applications can be produced with vertical casting machines from Primetals Technologies.

Vertical casting machines enable almost any steel grade to be cast. They are employed for the casting of steel grades that cannot be cast on a conventional bow-type caster. The advantages of vertical casters include the elimination of bending and straightening forces, optimal steel cleanliness, and a high homogeneity and symmetry of the cast slabs or blooms.