Stainless Rolling Mill

High reduction and excellent finish.

Stainless steel is characterized by high strength and an appealing finish. Various mill designs including KZR mill, HZ mill, and 6-high Universal Crown Control Mill (UC-MILL) with small-diameter work rolls are offered in tandem or single reversing configuration, in order to achieve efficient rolling of hard stainless products. For a smooth and aesthetic finish, Finishing Skin-Pass Mills with large diameter work rolls are integrated into Annealing and Pickling Lines (APL) and are also available as stand-alone reversing machines.

Line-up of solutions to effectively roll high-quality stainless products

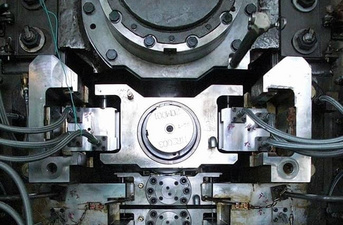

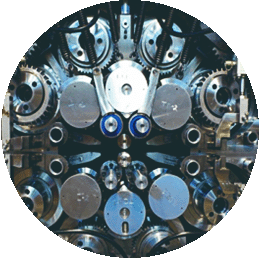

KZR Mill

The ZR mill is a 20-high roll cluster mill for rolling ultra-thin and/or high-strength material to the required product thickness and strip shape accuracy. Two ultra-small diameter rolls enable the rolling of special material thanks to their small roll indentation.

In a conventional ZR mill, only two backing bearings (B and C) are used for shape control (AS-U system). However, this control capability makes it difficult for high-speed rolling with high rolling reduction. To resolve this, we developed the KZR mill, which has a double AS-U system (A, B and C, D) and effective automatic shape control. Therefore, KZR mill can boost production rates for rolling high-strength material.

Want to know more? Go to Lifecycle Services & Integrated Plants & Solutions