News & Press Releases

London, October 22, 2021

World premiere: First commissioning of new type of mould level control for continuous casters by Primetals Technologies

- FAC obtained for first installation of a new type of mould level control on an Arvedi ESP line

- Controlled oscillation of the bending zone stabilizes strand bulging

- A new process now stabilizes the mould level in whole frequency range even at high casting speeds

Primetals Technologies has obtained the final acceptance certificate (FAC) for a new type of continuous casting control on an Arvedi ESP casting and rolling line. The "LevCon Bender Anti-Bulging" process patented by Primetals Technologies was commissioned for the first time anywhere in the world. The mould level in the continuous caster is stabilized by means of a controlled oscillation in the distance between opposite rollers in the bending section. This new type of process reduces the "bulging" effect of the strand on the mould level at high speeds much more effectively than by simply controlling the mould level via the steel flow into the mould. For the first time ever, it is now possible to compensate mould level fluctuations with higher frequencies.

New type of patented mould level control

Primetals Technologies' "LevCon Bender Anti-Bulging" is a process control for continuous casters and prevents fluctuations of the mould level caused by unsteady strand bulging. This control method counters the "pumping" of the mould level by means of position-controlled oscillations of the strand's hydraulically movable bending zone. These oscillations support the control of the mould level by the steel flow into the mould. This new process reduces the variations in the steel flow, thereby stabilizing the strand casting process.

Process even stabilizes at high casting speeds

The bulging effect of a strand is greater at high casting speeds, and higher frequencies occur. This makes such control particularly interesting for Arvedi ESP lines, which produces hot strip in a combined, continuous and uninterrupted casting and rolling process. The casting speed can reach more than six metres per minute and is therefore much higher than with "conventional” continuous casters, where it is often below two metres per minute. The new process has also been successfully deployed at low casting speeds.

LevCon Bender Anti-Bulging is a registered trademark of Primetals Technologies in a number of countries.

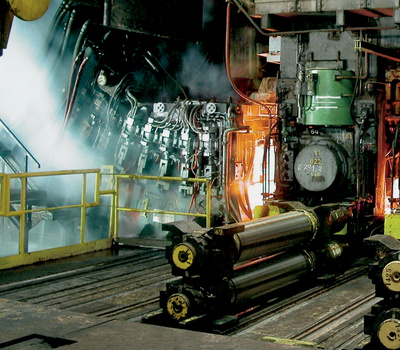

LevCon Bender Anti-Bulging by Primetals Technologies: A new process stabilizes the mould level by controlled oscillations of the bending zone.

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the finished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a joint venture of Mitsubishi Heavy Industries and partners, with around 7,000 employees worldwide. To learn more about Primetals Technologies, visit the company website www.primetals.com.