News & Press Releases

London, October 23, 2024

Primetals Technologies Wins Innovation Award for Green Ironmaking Solution

- Upper Austrian innovation award for companies that fuel progress through ground-breaking technologies

- Smelter is designed to replace blast furnaces

- Significant reduction of CO2 emissions

Primetals Technologies has recently received the “Innovation award” from the Upper Austrian government. The award was presented at a special ceremony in Linz, Austria on October 21.

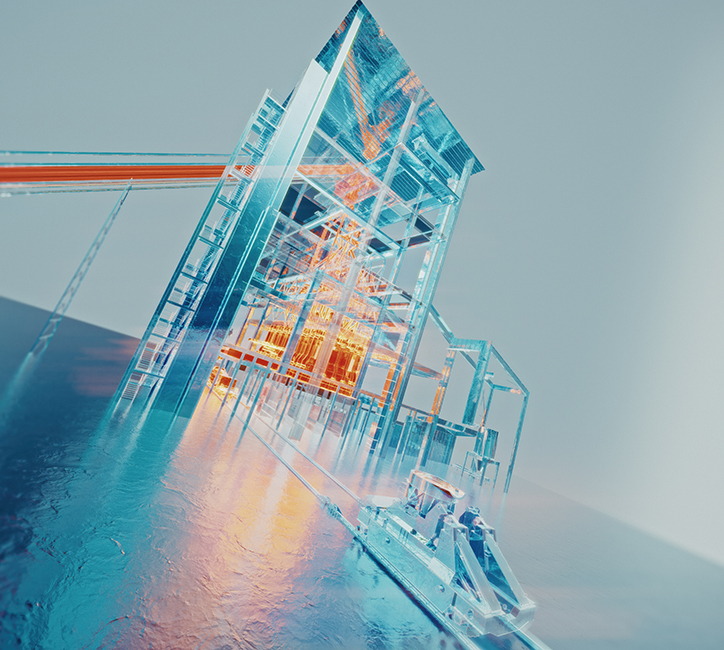

Smelter – a Solution for Production of Green Hot Metal

The Upper Austrian innovation award is given to companies that fuel progress through ground-breaking technologies. Primetals Technologies’ team that received the award has been developing the Smelter since 2022. This solution is a furnace powered by electrical energy used for melting and final reduction of direct reduced iron (DRI) based on lower-grade iron ores. It produces alternative green hot metal for the steelmaking plant.

“We are extremely thrilled and proud to win this prestigious award,” says Dr. Alexander Fleischanderl, CTO and Head of Green Steel at Primetals Technologies. “About 90 percent of the CO2 emissions in steelmaking comes from the blast furnace process, and this is still the main production route. We at Primetals Technologies are developing the Smelter to replace blast furnace plants – it is a key technology for sustainable ironmaking processes.”

A Green Steelmaking Route

Implementing the Smelter comes with two main cost-related benefits for steel producers. First, the direct reduction – Smelter – LD converter (BOF) route is utilized especially for low-grade iron ores, as it handles the generated slag well. With this route, the LD converter is kept after the Smelter has been implemented. Therefore, steel producers who operate integrated plants do not need to modify the rest of their production chain and do not have to renew their certifications when they invest in a Smelter.

Second, producers can keep the blast furnace running while installing the Smelter, and then discontinue the use of the old equipment as soon as the new furnace is ready for operation.

Primetals Technologies intends to implement the first continuously operating Smelter plant on voestalpine’s premises in Linz, Austria in close cooperation with the Austrian steel producer.

A part of the project team from Primetals Technologies at the award ceremony.

Smelter from Primetals Technologies produces alternative green hot metal. The technology has been awarded with an innovation prize from the Upper Austrian government.

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the finished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a Group Company of Mitsubishi Heavy Industries, with around 7,000 employees worldwide. To learn more about Primetals Technologies, visit the company website www.primetals.com.