News & Press Releases

-

London, June 21, 2022

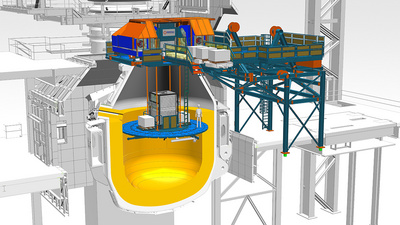

Brazilian customer CSP to improve safety and plant performance with new relining machine from Primetals Technologies

Recently, Brazilian steel producer Companhia Siderúrgica do Pecém (CSP) ordered a new relining machine from Primetals Technologies for its steel mill located in Pecém, a city in the state of Ceará, in north-eastern Brazil.

more

-

London, June 09, 2022

Indian customer places order with Primetals Technologies to increase production for the automotive industry

Steel producer ArcelorMittal Nippon Steel India (AM/NS India) recently ordered a coupled Pickling Line and Tandem Cold Mill (PLTCM) from Primetals Technologies for its site in Hazira, Gujarat in the western part of India.

more

-

London, May 18, 2022

Primetals Technologies launches new task force to lead transition to green steel

In April, Primetals Technologies appointed Dr. Alexander Fleischanderl as the Head of Green Steel. The main goal of the task force is to position the company as the frontrunner in green steel production solutions.

“I’m proud of being promoted to this position and I strongly believe that, together with the task force team, this effort will become a game-changer,” says Fleischanderl.

more

-

London, March 24, 2022

Primetals Technologies to convert a continuous tandem line into a pickling tandem line at voestalpine’s steel plant

Primetals Technologies has received a contract from voestalpine Stahl GmbH, a company of the Steel Division of voestalpine AG, to convert the existing continuous tandem line into a pickling tandem line at voestalpine’s site in Linz. The package includes core components, process machinery, and their integration into the existing plant.

more

-

London, March 17, 2022

Primetals Technologies receives final approval on drives upgrade for Nucor Steel Arkansas hot strip mill

Primetals Technologies has received the Final Acceptance Certificate (FAC) for its F5 and F6 main drive upgrade project with Nucor Steel Arkansas of Armorel, Arkansas. This completes the third phase of the total project: full replacement of the hot strip mill’s six main mill stand drives.

The main challenge in replacing the drives was to execute the changeover within the customer’s nine-day maximum outage time. To meet this extremely tight timeline, the very large drives had to include identical take-over points for all existing, equally large cables. The new Siemens Sinamics SL 150 drives also needed to start up and achieve full production immediately, without any ramp-up time. The team achieved hot commissioning 15 hours ahead of schedule.

more