News & Press Releases

-

London, August 31, 2022

Primetals Technologies and POSCO to develop new green steel demonstration plant

On July 26th, Primetals Technologies and South Korean leading steel producer POSCO signed a Memorandum of Understanding (MOU) to develop a demonstration plant for hydrogen-based hot metal production in South Korea.

more

-

London, August 25, 2022

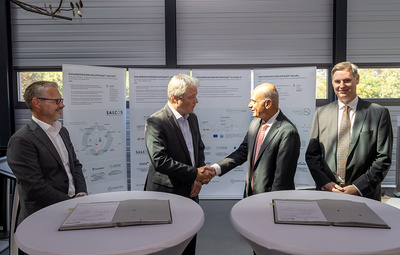

Salzgitter places large order with Primetals Technologies for electric arc furnace as part of major green steel transformation program

On August 23rd, German steel producer Salzgitter signed a contract with Primetals Technologies for an EAF Ultimate. Salzgitter is investing in the world’s leading transformation program in the steel sector. This order for one EAF with Primetals Technologies marks the first step in this process.

more

-

London, August 03, 2022

voestalpine implements first part of new process control system from Primetals Technologies

Primetals Technologies is modernizing the entire process control system at voestalpine’s LD3 steel plant in Linz, Austria. In June 2022, voestalpine completed the first modernization phase.

more

-

London, July 20, 2022

LD converter (BOF) supplied by Primetals Technologies starts up at ArcelorMittal’s steel plant in Gent

Recently, a new LD converter (BOF) implemented by Primetals Technologies was started up at ArcelorMittal Belgium’s steel plant in Gent, Belgium. To meet the demands on pre-assembly works, Primetals Technologies came up with several innovative ideas.

more

-

London, June 30, 2022

GravitHy, imminent market leader in green iron and steel, is launched today by world-class industrial consortium

A consortium composed of EIT InnoEnergy, the innovation engine for sustainable energy supported by the European Institute of Innovation & Technology, a body of the European Union (EU), Engie New Ventures, Plug, FORVIA, GROUPE IDEC through GROUPE IDEC INVEST INNOVATION and Primetals Technologies as a partner of the consortium, today launch GravitHy – a future market leader in green steel.

more