News & Press Releases

London, January 15, 2025

HBIS Starts up Slab Caster from Primetals Technologies Utilized for Green Automotive-Exposed Steel

- 1-strand continuous slab caster started up two weeks ahead of schedule

- HBIS XuanHua set to produce low-carbon steel for the automotive industry

- Primetals Technologies has supplied key mechanical scope and a comprehensive automation solution

Chinese steel producer HBIS XuanHua Iron and Steel Group and Primetals Technologies have recently started up a slab caster with an annual capacity of 1.5 million tons at a low-carbon-emission production facility in the Xuanhua district of Zhangjiakou city, Hebei province. Primetals Technologies is responsible for the full mechanical scope as well as a complete Level 1 and 2 automation system.

Leading Supplier of Casting Machines

The startup was completed two weeks ahead of schedule, marking a key project milestone. During the first heat, all systems were already operated in fully automated mode. This implementation is another proof of Primetals Technologies leading position both in terms of continuous casting technology and ability to complete projects on time through coordination and teamwork efforts. These were also the main reasons behind HBIS’ choice of supplier.

The slab caster implemented at HBIS XuanHua is characterized by its versatility: it will be utilized for a wide variety of steel grades as well as for stainless steel production. An advanced mold-oscillation technology, the DynaFlex hydraulic oscillator results in improved strand-surface quality of the produced slabs. Key mechanical solutions also include Smart Segments in the strand guide with online and remote adjustment of the roll-gap for flexible control of slab-width thickness changes, and DynaJet air-mist nozzles featuring an optimized spray pattern, allowing for optimal cooling of the strand. Mold Expert is an advanced system to automatically detect and prevent breakouts and to analyse the casting process in the mold.

Comprehensive Automation Solution

State-of-the-art process models ensures a high level of control over key production parameters. As an example, Dynacs 3D calculates the full 3D strand-temperature profile at any position along the strand. This enables optimal adjustment of secondary cooling setpoints and the point of final strand solidification. Yield Expert is a strand-length optimization system which considers factors like scrap portions, quality defects, weight limitations, and width changes to minimize the amount of scrap and optimize yield. In this way, productivity can be increased. Quality Expert tracks, supervises, and controls quality-related data and predictions for the cast products, contributing to ongoing improvement of the product quality.

HBIS Group is one of China´s largest iron and steel producers and is dedicated to producing high-end automobile plates, fine medium-thick plates, high-quality special steel, and products for the vanadium-titanium new materials industry.

HBIS’ plant in Xuanhua is recognised as the world’s first hydrogen-based iron- and steelmaking facility on an industrial scale. The 1-strand slab caster is now part of the production chain, which also consists of a DRI plant and electric steelmaking facilities. The close to zero-carbon steel produced at the site will be used in demanding sectors like the automotive industry.

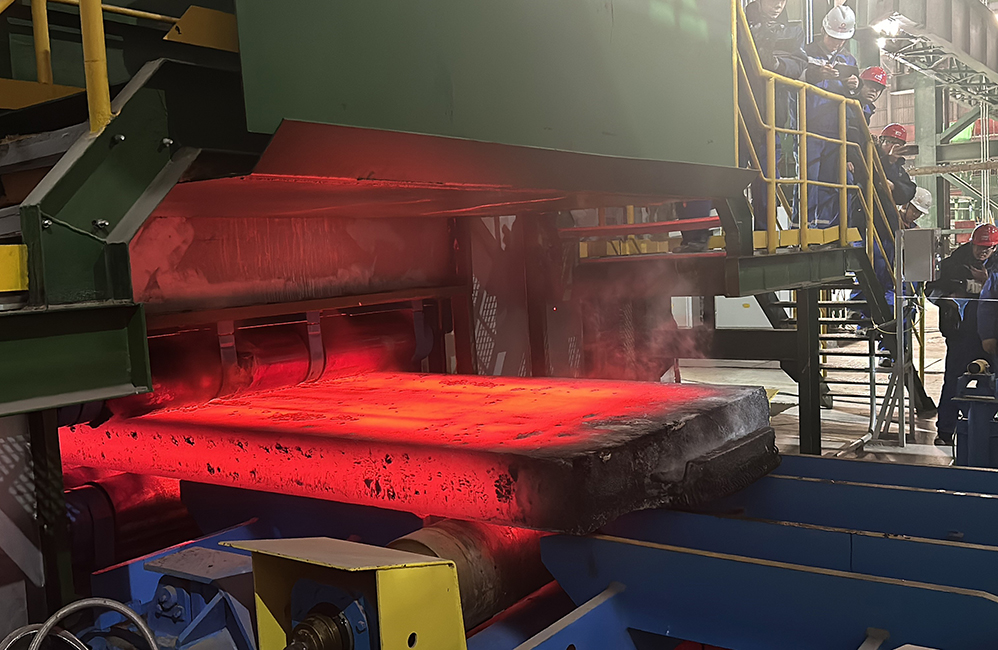

The Primetals Technologies caster startup team on site at HBIS XuanHua.

First slab produced on Xuanhua’s 1-strand slab caster from Primetals Technologies.

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the finished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a Group Company of Mitsubishi Heavy Industries, with around 7,000 employees worldwide. To learn more about Primetals Technologies, visit the company website www.primetals.com.