EAF Optimizer

Dynamic process optimization (Level 2) for Electric Steelmaking

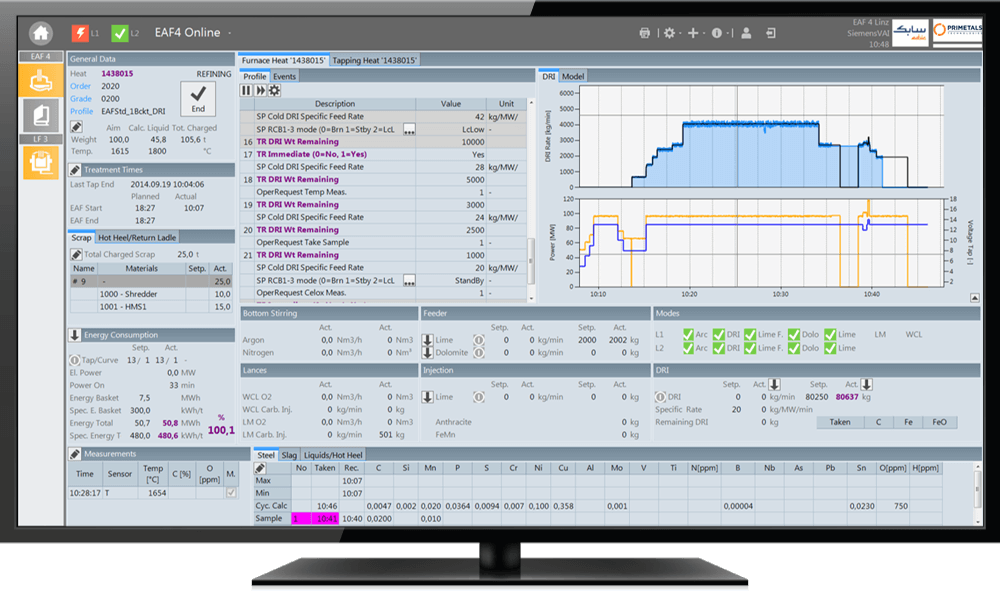

- Continuous online calculation and dynamic control of steel and slag properties during the EAF melting process

- Process visualization and operator guidance using a a state-of-the-art HMI

- Comprehensive reporting tools for heat logging, delay handling, and alarm generation

- Optimal raw material mix and adjusted melting control

- High raw material flexibility and maximum utilization of eletrical and chemical energy input for minimal conversion costs

- Reduced energy consumption

- Reduction of tap-to-tap time