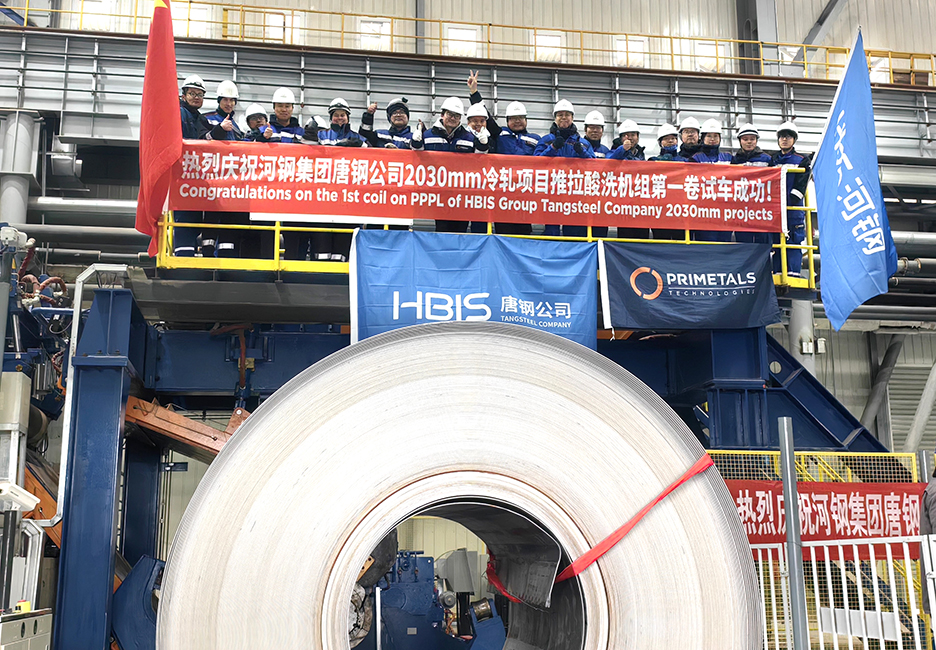

World’s Largest Push-Pull Pickling Line Produces First Coil at Tangsteel, China

- Primetals Technologies has implemented a push-pull pickling line for strip thicknesses from 1.8 to 15 millimeters and process speeds of up to 200 meters per minute

- Enables a very wide product mix usually possible only with two conventional continuous pickling lines

- In-line skin-pass mill for enhanced control of strip flatness

Primetals Technologies has recently implemented the world’s largest push-pull pickling line (PPPL) at Chinese steel producer HBIS Tangsteel’s steel plant in Laoting, Hebei province, China. The first pickled coil was successfully produced in December 2023. Primetals Technologies provided the full mechanical and electrics and automation scope and was responsible for engineering as well as advisory services for the implementation.

Extremely Wide Product Range

The core aim of Primetals Technologies’ push-pull pickling line is to enable an extraordinarily wide product range in terms of strip dimension, steel grade properties, and production capacity. This is normally achieved by operating both a conventional continuous pickling line and a PPPL in parallel. As a result, Primetals Technologies’ PPPL offers a clear advantage over conventional push-pull pickling lines from a flexibility perspective.

HBIS Tangsteel’s PPPL features an in-line 4-high single-stand skin-pass mill. A flatness control system adjusts the mechanical properties by allowing for controlled elongation. Thanks to the skin-pass mill, PPPL operators have even more control over strip flatness.

Maximized Throughput

Supported by an innovative solution for automated analysis and control of the pickling process, personnel at HBIS Tangsteel now have an extensive overview of all aspects of the process and are able to control it in a highly precise way. A part of the comprehensive Level 2 automation solution, the system is backed by a sophisticated pickling software model that considers numerous parameters related to the incoming strip. It was designed to ensure optimal operating conditions regarding temperature, pickling levels, flows, and turbulence. The application of the pickling model leads to a major increase in throughput capacity while ensuring optimal energy use and minimized consumption of pickling fluid.

The PPPL also features a turret-head-type side trimmer processing thicknesses from two to eight millimeters. This type of highly effective trimmer increases the throughput and maximizes strip-edge quality.

Ships to more than 100 countries

The backbone and largest steel subsidiary of HBIS, HBIS Tangsteel is one of the biggest state-owned iron and steel enterprises in China. The main products of Tangsteel are: hot-rolled and cold-rolled sheet, galvanized sheet, medium and heavy plate, as well as bar, wire, and section products, which are widely used in automobiles, appliances, machinery manufacturing, infrastructure, bridge construction, and other sectors. The products are shipped to more than 100 countries across the world. Tangsteel is committed to providing the most valuable steel materials and comprehensive service solutions for downstream businesses.

The Primetals Technologies team, celebrating the first coil at the world’s largest push-pull pickling line (PPPL).