Automation & Digital Plants

The factory of the future – smart, safe, reliable, and fully automated

Primetals Technologies combines automated systems with digitalization solutions to create the fully automated plant of the future. Our innovations improve safety and reliability, allowing operators and machines to work together to bring high-quality end products to the market, meeting and exceeding ever-changing demands. Transforming digital insights into automated actions, Primetals Technologies provides modernization solutions to improve, augment, automate, and digitalize every aspect of your plant, from raw materials to end products.

Automation

Integrated electrics and automation solutions for the whole lifetime of metallurgical plants

We offer a comprehensive spectrum of cost-effective automation applications for all iron and steel production units from one single source. Our portfolio includes powerful process control, stable process optimization systems, and combined mechatronics and automation solutions to increase profitability, improve flexibility, and optimize the process and product quality of current and future steelworks.

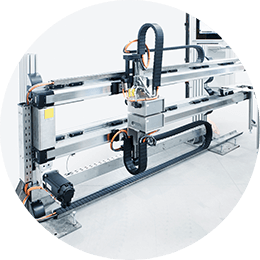

Smart sensors and automatic functions

A wide range of intelligent solutions for transparent, reliable, and safe operation

To ensure that each production facility can play its part in the digital plant, it has to fulfill certain preconditions, meaning that it must have the highest possible degree of automation combined with high availability. Smart sensors, monitoring tools, and robotic applications make a significant contribution here by leading to greater transparency of all production steps and enabling the systems to operate automatically.

Digital Unity

Synchronize your production to achieve the full potential of your steel factory

Smart sensors, automatic functions and cyber-physical systems digitize your plant. Connectivity of plant equipment and data-based assistance of the workforce’s day-to-day agendas are essential factors shaping the future of metals production. Digital Unity is a digitalization-driven concept that integrates data from three key processes: production, quality, and maintenance. It consists of three digital software services: Production Management System (PMS), Through-Process Optimization (TPO), and Maintenance Asset Technology (MAT).

Intralogistics

Intelligent intralogistics solutions for increased profitability

Increasing pressure to optimize flexibility, productivity, and the quality of the steel manufactured means that digitalized, predictable, and optimized intralogistics processes are essential. Primetals Technologies offers solutions based on the digitalization of all key intralogistics processes, which allows for improved raw material quality, minimized production buffers, increased output, greater profitability, a more efficient flow of materials and goods, and predictable and transparent intralogistics processes.

Metals Intelligence

Convert your data into insights and actions

The performance of a highly automated steel plant can significantly be improved by leveraging the power of existing data. Production data should be stored in a structured way in a Data Warehouse. Business Intelligence tools provide answers to production-related questions. Data-driven methods can generate insights into how to improve a steel plant's performance. Ideally, these insights are automatically converted into standardized actions. Digital assistants provide recommended actions and supervise operators.

Smart Services

Electrics & Automation Services

Primetals Technologies values long-term lifecycle partnerships and is dedicated to minimizing downtimes, reducing operational costs, ensuring staff safety, and increasing availability and productivity. Our global service team's vast range of electrics and automation service solutions is designed to support every operational phase in steel production. These solutions encompass service contracts, consulting and software and hardware engineering, maintenance activities management, and migration and upgrade strategies.

Motors & Drives

Innovative drive systems customized to meet the needs of your plant

Steel plants, especially rolling mills and processing lines, depend mainly on uninterruptible processes and the quality of the steel rolled. Our drives are dimensioned per the customer's plants and metallurgical process and can be integrated seamlessly into higher-level automation systems. We deliver the complete drive system: transformers, converters, and motors – matched precisely to each other.

Power

Energy supply and power quality — solutions for substations and power distribution

Primetals Technologies offers reliable power distribution and quality solutions tailored to your technological process needs and utility supply requirements. We create a solid design basis for your distribution solutions by using our extensive know-how in the fields of high, medium, and low-voltage systems, along with the specific needs of your technological processes and maintenance requirements. We provide a safe energy supply by meeting and exceeding industry-leading safety standards and codes.