ENERGY EFFICIENCY — EFFICIENCY UP – COSTS DOWN

Primetals Technologies offers a wide range of advanced technologies, services, automation solutions, plant upgrades and modernization packages to make steel manufacturing as energy – efficient as possible. Get the best out of your plant – follow the three essential steps towards more energy efficiency: Energy check, Feasibility Study, Specific improvement

Energy efficiency technologies for ironmaking plants

Preheating of combustion air

Implementation of a heat exchanger in the recuperation duct for heating up the combustion air of the burner system.

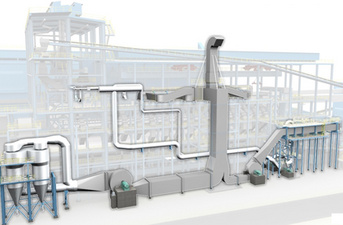

Selective Waste Gas Recirculation (SWGR) – Energy efficiency for sinter

Primetals Technologies has developed and implemented the Selective Waste Gas Recirculation (SWGR) system to reduce environmental emissions from sinter production. With the SWGR system, offgas from selected zones of the sinter machine is mixed with hot cooler off-air and then recirculated to the sinter strand. The result is a significant reduction of the specific offgas volume to the end-of-pipe gas cleaning by up to 50%.

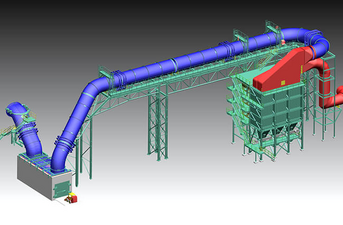

Sinter cooler waste heat recovery – Transform sinter waste energy into profit

The sensible heat of the sinter that is discharged from the sinter machine to the sinter cooler amounts to almost half of the total process thermal energy input. Primetals Technologies has developed solutions for efficient recovery of this sensible energy by utilization of hot waste air from the sinter cooler for production of steam. Special off-air recirculation concepts lead to increased plant efficiency and additionally ensure compliance with local emission standards.

Top gas Recovery Turbine (TRT) – Transform off-gas into profit

The blast furnace process consumes upward of 75% of the total energy in an integrated steel plant. The TRT recovers the pressure energy of the top gas of a blast furnace by controlled expansion to low clean-gas pressure. Electrical energy from the waste pressure can be gained without any additional energy input or CO2 production.

Dry slag granulation with heat recovery – Utilization of blast furnace slag heat energy

Primetals Technologies, voestalpine Stahl, the FEhS – Building Materials Institute and the University of Leoben joined forces in an R&D program to develop a new dry-granulation technology using air to cool molten slag and recover the lost heat energy. The slag granulate from this process fulfills the same criteria as wet-granulated slag for use in the cement industry.

Click here to learn more about our gas-cleaning portfolio for ironmaking facilities.

Energy efficiency technologies for steelmaking plants

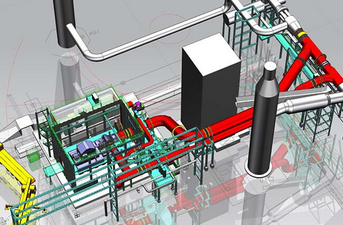

Gas recovery

LD (BOF) gas recovery is an economic solution for LD (BOF) primary waste gas treatment that is completely integrated. The main equipment for the LD (BOF) gas recovery is the gasholder plus the pressure boosters and distribution network. Beside the high efficiency the main focus is on advanced operation safety.

Cooling stack – Highly efficient energy recovery

Converter waste gas cooling is highly challenging due to the tough operating conditions with high loads of abrasive dust particles as well as high temperatures and the general cyclic nature of this batch process. Primetals Technologies ensures high plant availability and best performance by applying state-of-the-art and proven designs and materials and advanced dynamic simulation of process conditions

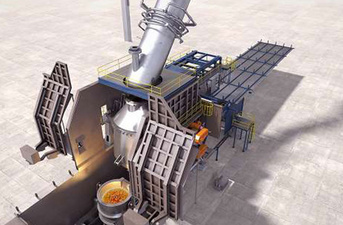

Energy recovery for electric arc furnaces – Highly efficient waste heat recovery

Most electric arc furnace offgas systems are not thermally optimized, so only nearly 30% of the energy input in the electric arc furnace is used further. Primetals Technologies provides electric arc furnace operators with highly efficient energy recovery systems. The integral approach is based on a modular dedusting system set-up. Basically, either the hot gas line or the forced-draft cooler or both aggregates can be exchanged by an adequate energy recovery system.

AOD waste heat recovery – Solutions for highly efficient energy recovery

A two stage solution helps customer to optimize waste heat recovery in accordance with waste heat utilization. Depending on the individual requirements the first cooling stage for the AOD waste heat recovery system can be realized either as hot water or steam cooled equipment. Additionally the second stage cooling equipment can be replaced by an waste heat boiler or an heat exchanger.

Click here to learn more about our gas-cleaning portfolio for steelmaking facilities.

Reference Story: Highest efficiency & safety for LD (BOF) gas recovery

Customer

TATA Steel Port Talbot, England

Typ of plant

Gas recovery system for LD (BOF)

Our solution

Although equipped with a suppressed combustion primary dedusting system, the steel shop of TATA Steel Port Talbot (former CORUS), did not feature a gas recovery system until Primetals Technologies was awarded the contract to install the energy recovery system. Jointly with TATA Port Talbot we developed the project according to the highest safety standards in Europe and with smallest impact on ongoing plant operation.