BLOOM CASTING — HIGH-PERFORMANCE, POWERFUL MACHINES TO MEET THE MARKET REQUIREMENTS

Primetals Technologies offers bloom casters which combine metallurgical and technical expertise in innovative production equipment, manufacturing processes and control systems.

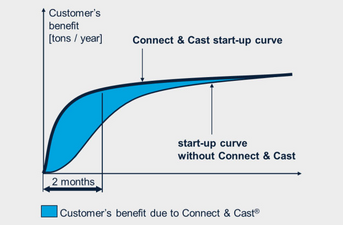

Thanks to the connect and cast principle machines from Primetals Technologies have the shortest ramp-up time on the market. No matter if you build up a new plant or like to modernize your existing plant. This has been proven in more than 100 installations. We support our customers not only during the project phase: We are there throughout the integration phase, into full production and beyond – thanks to our lifecycle management services.

Bloom Casting

In the intensely competitive environment of the steel industry, a high degree of flexibility, product quality and customer orientation is absolutely essential for lasting success. In the process itself, casting speeds have been rising and the spectrum of possible dimensions and materials have been expanding continually.

Through the use of technological packages and consequently following our connect&cast principle, we achieve the shortest start-up times in the industry. Our modular solution approach ideally meets all technological requirements and customer demands, for both new and existing casters and for the production of carbon, stainless and special steel grades.

The ever-greater demands for quality and the ongoing development of steel grades mean that the quality level at every stage of the casting process will continue to grow in importance in the future. As an example the DynaFlex oscillation technology from Primetals Technologies represents the latest generation of oscillation systems and saves money in operation compared to other systems. The hydraulic oscillation drive system enables the dynamic adjustment of frequency, stroke, and wave form during casting for optimized negative strip time. The wear-free leaf-spring oscillator guidance system guarantees the highest guidance accuracy, outstanding operational safety, and low maintenance costs. The design allows a quick coupling of all media supplies to the mold and automatically completes the alignment of the mold and oscillator.

Primetals Technologies has the metallurgical experience and technical expertise to supply cuttting-edge technology for maximized bloom caster performance, production and upgrading.

Further highlighted products:

- LevCon: advanced mold level control with upmost precision under all casting conditions

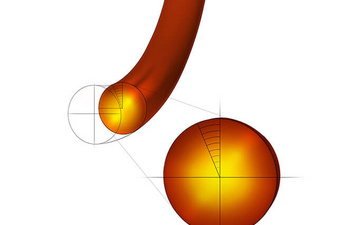

- DiaMold: copper tube for rapid casting of rounds and square

- DynaJet: high-precision secondary cooling spray nozzles

- DynaTac: high temperature casting package

- OPAL: integrated laser measuring system

- DryStar Spiral: strand guide roller for high temperature casting

Want to know more? Go to Integrated Plants & Solutions

Electrics and automation for continuous casting

Primetals Technologies offers a comprehensive range of process control solutions, technological packages and process optimization models that cover all aspects of the continuous casting process.

An outstanding example for optimizing the casting process with automation is the new model suite comprising DynaPhase, Dynacs 3D and DynaGap Soft Reduction 3D.

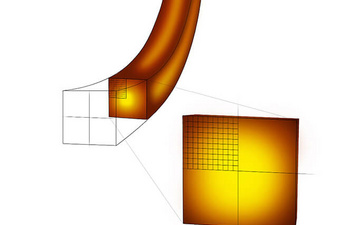

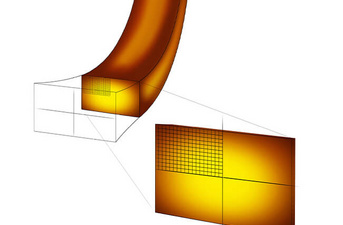

In order to calculate a 3-dimensional temperature profile of the strand material properties like enthalpy, solid fraction, density and conductivity as a function of the temperature have to be known. The traditional approach is to define these thermo-physical properties for steel grade groups. With DynaPhase the material properties are derived online from the actual steel analysis.

The Dynacs 3D advanced secondary cooling model calculates in real time a full three-dimensional temperature profile of the hot strand. Dynacs 3D accurately assesses the heat transfer from the slab surface and calculates the water flow setpoints to assures a stable strand surface temperature profile even in transient casting conditions

On the basis of the online information provided by Dynacs 3D, the DynaGap Soft Reduction 3D model dynamically calculates the setpoints of the adjustable roll gap. Supervision of the roll engagement, depending on the state of solidification (liquid, mushy or solid) and the calculated strand-thickness profile, is a decisive factor for precise roll adjustments and thus improved product quality. An optimized roll engagement also reduces excessive forces on the strand and decreases roller wear.

Further highlighted technological packages and process experts:

- LevCon: advanced mold level control with upmost precision under all casting conditions

- Mold Expert: more than just a breakout pre-detection system

- Quality Expert: a milestone in improved quality supervision, quality prediction and control

- Yield Expert: cut length/weight optimization for minimized scrap and optimized yield

- Intermix Expert: precise determination of the mixing area of different grades on the strand

- Nozzle Expert: highest accuracy in detecting clogged nozzles and broken hoses

- Speed Expert: optimal casting speed for increased throughput and improved quality

- DynaFlex: hydraulic Oscillator for perfect surface quality

ECO Solutions for bloom casting — Saving resources, creating value

Please follow the corresponding links to learn more about our competences:

Gas Cleaning

ECO Consulting

TECHNOLOGY AND MODERNIZATION PACKAGES

Get striking results with incremental investments

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|