SINTER TECHNOLOGY — HIGH-PERFORMANCE AND ENVIRONMENTALLY FRIENDLY SOLUTIONS

Sinter technology developed by Primetals Technologies ensures high and stable sinter quality for optimized blast furnace operation, a high degree of flexibility of raw materials, and low operating costs.

Requirements for availability, product quality and productivity of sinter plants are continuously growing. At the same time, environmental regulations are becoming increasingly stringent and require innovative solutions. As a full-liner in the metallurgical industry and a leading technology supplier of sinter plants, we strive to create exceptional technical solutions that meet the latest environmental requirements and consider economical aspects. This applies to new plants as well as to modernizations and plant upgrades. With 5 decades of experience, we are proud to be a technology leader in travelling grate solutions.

HIGH SINTER QUALITY AT LOW COSTS

Primetals Technologies is renowned for introducing state-of-the-art sinter plant solutions to the market. The latest developments include technology packages such as the Selective Waste Gas Recirculation system for reduction of off-gas emissions by up to 50%, or shaft cooler technology for zero emissions and 100% energy recovery. Or MEROS®, a fully-integrated modular off-gas cleaning system that ensures environmental compatibility at the highest level. The smart combination of mechanical equipment and intelligent automation expert systems is our specialty. Find out more:

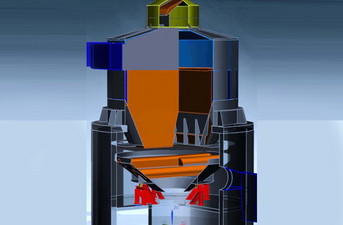

Sinter shaft cooler

Zero emissions and maximum energy recovery

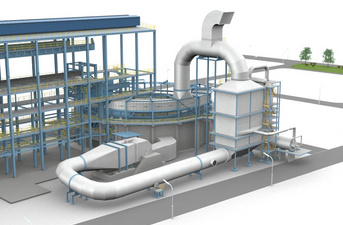

Selective Waste Gas Recirculation system (SWGR)

Reduced off-gas volume and coke reduction

Raw Mix Analyzer

Optimization of plant performance and productivity

Modernization packages

- Advanced cooler charging chute design

- Pallet car widening for capacity increase

Plant optimization studies and audits

Performance improvement; environmental audit; waste material management, capacity increase

Raw material and sinter tests (pot test)

Understanding the characteristics of raw materials in sintering is key to optimized production

Want to know more? Go to Lifecycle Services &Integrated Plants & Solutions

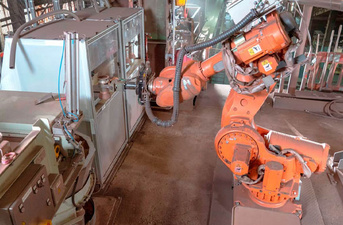

Intelligent automation for sinter plants

The sinter control system in combination with the sinter optimization system creates the next level in intelligent sinter automation. The optimal interaction between sophisticated models and the expert system provides extended assistance to plant operators and minimizes the risk of human errors.

Our solutions

Our reliable and most advanced process control system combined with our process optimization system provides major cost savings and process improvements without compromising raw material selection, sinter quality, energy efficiency, and productivity.

The optimized raw mix calculation with precise chemical targets and additional control loops is the basis for producing sinter of the highest quality, while at the same time effectively reducing coke consumption. The optimal position and control of the burn-through point, together with the homogeneous flame front, and optimal raw-mix moisture result in maximum productivity.

The system guarantees shift-independent plant operation where manual interactions are reduced to a minimum. The result is smooth sinter plant operation 24/7, increased equipment lifetime, and reduced production costs.

Advantages

- High productivity: sinter plant is running at peak performance while minimizing consumption of fuel and electrical energy for waste gas fans

- Product quality: chemical and physical properties of the sinter product maintained at the desired levels

- Reduced fuel consumption: precise mixing of charged materials results in homogeneous quantity of return fines

- Stable and shift-independent operation: best-practice sinter plant operation 24 hours a day to ensure efficient production

- Fast response to market demands: quick and flexible reactions to market requirements as well as unexpected situations

- Return on investment: the standard period is expected to be less than one year

ECO Solutions for sinter plants — Saving resources, creating value

Please follow the corresponding links to learn more about our competences.

Gas Cleaning

Energy Efficiency

By-Product Recycling

ECO Consulting

TECHNOLOGY AND MODERNIZATION PACKAGES

Get striking results with incremental investments

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|