News & Press Releases

-

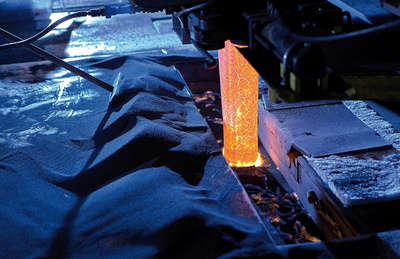

Guilin Pinggang issues FAC for EAF Quantum electric arc furnace and ladle furnace supplied by Primetals Technologies

In June, Chinese steel producer Guilin Pinggang Iron and Steel Co., Ltd. (Guilin Pinggang) issued the final acceptance certificate (FAC) for an EAF Quantum electric arc furnace with a tapping weight of 120 metric tons and a 120 metric ton twin ladle furnace supplied by Primetals Technologies. The furnaces were set up in a new production facility in Pingle near Guilin in Guangxi Province, which is intended to serve the growing market for rebars. The EAF Quantum is designed to handle scrap steel of varying composition and quality. The electrical energy requirement of the electric arc furnace is extremely low because the scrap is preheated.

more

-

First Coil produced on Hyper UC-mill supplied by Primetals Technologies to SUNSCO in Vietnam

The Hyper UC-mill supplied by Primetals Technologies (Primetals Technologies Ltd.) produced the first coil at Ho Chi Minh steel mill of Maruichi Sun Steel Joint Stock Company (SUNSCO). This is the first Hyper UC-mill in Vietnam, and by adopting the smaller diameter work roll drive with MH Spindle that withstands high load, it can reduce rolling loads while maintaining the high shape control capability of the UC-mill. The purpose of this project is to accommodate the growing demand for thinner cold rolled materials. This new light-duty Hyper UC-mill enables to reduce investment and maintenance costs. SUNSCO will build a stable position in the growing market for thinner cold rolled materials.

more

-

HYFOR pilot plant under operation – the next step for carbon free, hydrogen-based direct reduction is done

In April, the Hydrogen-based fine-ore reduction (HYFOR) pilot plant developed by Primetals Technologies was commissioned at the voestalpine site in Donawitz, Austria. First tests were successful. Test with various iron ore concentrates will continue to collect a sound data basis. Use of 100% Hydrogen as reduction agent reduces the CO2 footprint close to zero. The HYFOR pilot plant employs the world´s first direct reduction process for iron ore fines concentrates from ore beneficiation, not requiring any agglomeration like sintering or pelletizing. This reduces CAPEX and OPEX costs. HYFOR represents the only process worldwide capable of processing iron ore concentrate fines with 100% particle sizes smaller than 0.15 mm, and a wide variety of ores, e.g. hematite and magnetite, supplied by different customers of Primetals Technologies worldwide. The direct reduction plant will come in a modular design, allowing for a tailor-made scaling for customers for all sizes of steel plants.

more

-

Primetals Technologies receives final acceptance certificate for three Mold Expert systems from Tangshan Heavy Plate

In March 2021, Tangshan Heavy Plate issued Primetals Technologies with the final acceptance certificate (FAC) for three Mold Expert systems for the continuous casters at the Laoting plant in the Tangshan region of China. The new systems have been installed to increase efficiency even more in the prevention of breakouts on the continuous casters and cut the amount of maintenance work. Reducing the frequency of breakouts will also help to lower production costs. Primetals Technologies China commissioned the new systems on site with online support from experts at Primetals Technologies Austria. Despite travel restrictions, the project was realized within just three months. Before the order was placed, Primetals Technologies ran and supported a six-month test installation on one of the casters.

more

-

ArcelorMittal Zenica orders converter replacement from Primetals Technologies

In April, Bosnian steel producer ArcelorMittal Zenica d.o.o. placed an order with Primetals Technologies to replace the vessel of BOF converter #2 and supply associated equipment. An optimized design will increase the vessel volume and make production easier. The well-proven Vaicon Link 2.0 suspension system eliminates maintenance requirements. A new design of the exchangeable bottom ensures reliable sealing and minimizes the risk for leakages. The converter replacement will be executed in an open consortium with the experienced Serbian company GrappS d.o.o. as installation partner. Start-up of the converter is expected by end of 2022.

more