News & Press Releases

London, June 17, 2021

Primetals Technologies receives final acceptance certificate for three Mold Expert systems from Tangshan Heavy Plate

- Reduced production costs due to fewer breakouts

- Increased plant availability and less time spent on maintenance

- On-site commissioning by Primetals Technologies China and remote support from Primetals Technologies Austria

- Project realized within just three months despite travel restrictions

In March 2021, Tangshan Heavy Plate issued Primetals Technologies with the final acceptance certificate (FAC) for three Mold Expert systems for the continuous casters at the Laoting plant in the Tangshan region of China. The new systems have been installed to increase efficiency even more in the prevention of breakouts on the continuous casters and cut the amount of maintenance work. Reducing the frequency of breakouts will also help to lower production costs. Primetals Technologies China commissioned the new systems on site with online support from experts at Primetals Technologies Austria. Despite travel restrictions, the project was realized within just three months. Before the order was placed, Primetals Technologies ran and supported a six-month test installation on one of the casters.

Increased plant availability, less time spent on maintenance, and reduced production costs

Tangshan Heavy Plate has invested in three Mold Expert systems for its existing continuous casters at the Laoting plant in Tangshan in China. The new solutions from Primetals Technologies have been installed to increase system availability at the Laoting plant and reduce the amount of time spent on maintenance by issuing prompt alerts. Apart from preventing breakouts, the system also transmits alerts in the event of abnormal casting conditions and evaluates the behavior and distribution of the mold powder. Continuous recording of information and experiences in the Mold Expert system results in more efficient prevention of breakouts in real-time operation, thus avoiding high costs for repairs and production outages. The system provides data for process optimization and supports the operator in his work. The software can be easily scaled to meet the customer's specific needs.

Custom configuration of system hardware

In the standard configuration, each Mold Expert system is deployed with one computer for measuring tasks and a separate client PC. However, to fulfil the customer's wishes and requirements in this specific project, a particularly "slim-line" version of the system was implemented with the entire software installed on just one computer in the operator room for each continuous caster.

Efficient project execution despite travel restrictions

Employees from Primetals Technologies China successfully carried out commissioning on site with experts from Primetals Technologies Austria assisting online whenever their help was needed. Despite travel restrictions, the project was realized within just three months. Commissioning was greatly facilitated by information on the plant gathered by analyzing actual data during a prior six month test installation. Furthermore, the teams from Tangshan Heavy Plate and Primetals Technologies had the opportunity to develop a relationship based on mutual trust during the six-month test phase. This was a further important element in ensuring smooth-running commissioning.

Joint venture

On September 1, 2017, the Primetals Tangshan Technology Services Ltd. (PTTS) joint venture was established between Primetals Technologies and HBIS Tangshan Iron and Steel Group (Tangsteel).

The joint venture's headquarters is located in Tangshan in China. PTTS operates primarily at various locations in the Hebei province. The aim of the joint venture is to stimulate an exchange of technology. The joint venture provides extensive, technology-based services in offline maintenance, equipment overhauls, condition monitoring, and operational support for the slab casters run by Tangsteel and other customers. With its workforce of around 500 employees, the company draws on Primetals Technologies' proprietary, protected maintenance technologies and know-how to further improve operating efficiency and product quality.

Headquartered in Tangshan in China, HBIS Tangsteel is a leading steel company and the backbone of the HBIS Group. Every year HBIS Tangsteel produces 18 million metric tons of flat, bar, wire and section products. Its main products include high strength auto sheet, hot-rolled and cold-rolled sheet, galvanized sheet, color-coated sheet, medium and heavy plate as well as stainless steel strip, bar, wire and section products in a range encompassing 140 types, with quality flats accounting for 60%. The products are widely used in the construction, automotive, coal, machinery, energy, transportation, household appliance and other sectors in over 150 countries in Europe, the USA, Africa and Southeast Asia. HBIS Tangsteel employees 33,000 people within and outside of its steel division.

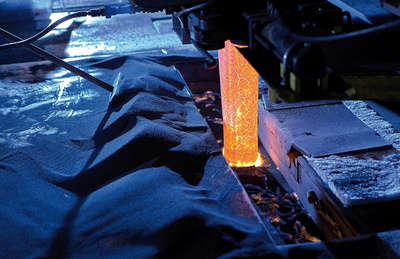

Primetals Technologies' Mold Expert prevents breakouts on continuous casters and reduces the amount of maintenance work.

Primetals Technologies, Limited, headquartered in London, United Kingdom, is a pioneer and world leader in the fields of engineering, plant building, and the provision of lifecycle services for the metals industry. The company offers a complete technology, product, and services portfolio that includes integrated electrics and automation, digitalization, and environmental solutions. This covers every step of the iron and steel production chain—from the raw materials to the finished product—and includes the latest rolling solutions for the nonferrous metals sector. Primetals Technologies is a joint venture of Mitsubishi Heavy Industries and partners, with around 7,000 employees worldwide. To learn more about Primetals Technologies, visit the company website www.primetals.com.