STRIP PROCESSING — SOLUTIONS TO MEET THE HIGHEST THROUGHPUT AND QUALITY DEMANDS

Strip processing lines stand for high-performance and cost-efficient strip processing that meet the demands of high-end markets.

PICKLING LINES — CLEAN AND SCALE-FREE SURFACES FOR OPTIMIZED DOWNSTREAM PROCESSES

The increasing demand for advanced steel grades and added value products drives steel producers to seek a more efficient pickling process.

Pickling Lines have to be optimized and ready to process many different steel grades, and provide precise control of strip tension, accurate strip guiding, high quality pickling control, fast and stable processes with faultless strip tracking.

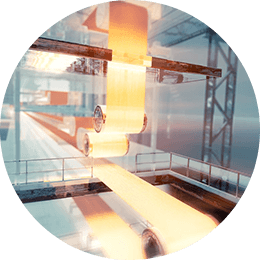

CONTINUOUS ANNEALING LINES — FUTURE-ORIENTED SOLUTIONS FOR DEMANDING PRODUCTS

Advanced annealing lines are essential for ensuring precisely controlled metallurgical properties and high processing speeds.

The Continuous Annealing Lines from Primetals Technologies feature a flexible, multi-zone furnace capable of processing a broad range of steel grades and dimensions at very high speeds. Line equipment includes fully automatic coil handling, mashed lap welder, highly efficient strip-cleaning, Skin-Pass Mill, Side Trimmer, state-of-the-art drives, and automation solutions.

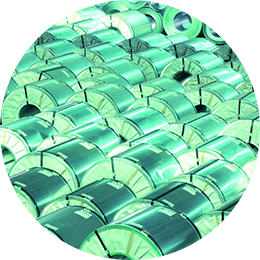

METALLIC COATING LINES — ADDING VALUE FOR A WIDE RANGE OF APPLICATIONS

A major trend in the steel industry is increasing added-value and profit margin on rolled product through the application of metal coatings.

A broad range of solutions is offered for metallic coating of both hot-rolled and cold-rolled strip in continuous hot-dip coating lines. This value-added, high-quality material is extensively used in construction, in appliances, in automotive and in packaging applications as a well-proven and time-tested solution for corrosion protection.

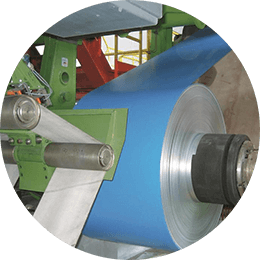

ORGANIC COATING LINES — COLORFUL PRODUCTS FOR CORROSION-PROTECTION APPLICATIONS

Continuous Coating Lines offer high throughput rates, reliability, and flexibility, and provide the basis for outstanding strip-coating quality.

Primetals Technologies offers a full spectrum of solutions to meet the requirements for a wide range of product applications. The strictest demands for high-end applications are fully met, such as in the automotive and household appliance industries. Both primary and secondary organic coating layers can be imparted to both sides of the strip.

STAINLESS ANNEALING AND PICKLING LINES — EFFICIENT, RELIABLE, ECONOMIC

Stainless Lines combine the traditionally separate processes of annealing and pickling, skin passing, and leveling in one integrated line.

Primetals Technologies’ Stainless Annealing and Pickling Lines (APL) include various combinations of processes, such as annealing, pickling, skin passing, and leveling, and can be designed for hot-rolled and/or for cold-rolled products.

RECOILING AND LEVELING LINES — ADDING THE FINAL TOUCH TO HIGH-QUALITY PRODUCTS

High-performing lines that enable you to meet your quality requirements and minimize rejection rates.

Primetals Technologies is able to supply high-performance finishing lines thanks to the special equipment assembled and tested in our workshop: tension Leveler, Skin-Pass Mill, Side Trimmer, and Shears, which can be coupled with upstream processes and inspection systems. These lines are aimed at processing semi-finished products for all types of application: construction, household appliances, or automotive products. Frequently positioned after strip processing lines, such as pickling, galvanizing, painting or annealing, these lines will incorporate, on-demand, various processes to ensure your products have the required added value.