WORLD-CLASS TECHNOLOGIES FOR ALUMINUM ROLLING

With over 90 years’ experience in the aluminum industry, Primetals Technologies is your single-source supplier for aluminum rolling solutions.

Our rolling mill technologies focus on enabling customers to roll faster, thinner, and wider, with the included benefits of higher outputs, tighter product tolerances, enhanced operational flexibility and efficiency, increased plant availability, reduced costs, and maximum environmental compatibility. After the successful completion of more than 350 aluminum rolling mill projects, Primetals Technologies is ideally positioned to offer expert advice and to implement the optimum rolling solutions for both new and existing plants.

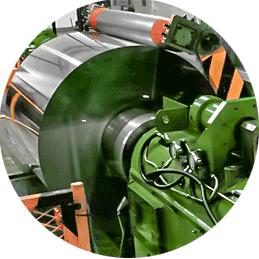

ALUMINUM HOT ROLLING MILL — HIGH-QUALITY PRODUCT & MAXIMUM MATERIAL YIELD

Primetals Technologies provides a full range of aluminum hot rolling mills for both new and revamp projects.

As the demand for higher quality and greater quantities of rolled aluminum increases, so do demands on production equipment. Primetals Technologies' solution offers a combination of mechanical actuators, electrical and automation control systems, and applied process know-how to deliver gauge, profile/flatness, temperature, and surface quality with the highest level of consistency. With our flexible mill configuration, high-quality strip can be rolled in capacities between 100,000 to 1,000,000 tonnes per annum.

ALUMINUM COLD ROLLING MILL — HIGH-PRECISION MILL FOR BREAKDOWN & FINISHING

Primetals Technologies' aluminum cold rolling mills offer a blend of innovative design and proven technology for both new and revamp projects.

From transport to construction, from packaging to automotive, each end market for flat rolled aluminum comes with its own set of production challenges. Primetals Technologies' aluminum portfolio provides you with the optimum equipment, correct mill setup, and control systems crucial to meeting exacting quality requirements. Our online modelling solutions feature fully integrated process control, automation and drive systems, delivering exceptional rolling results and enabling tight tolerance strip production with maximum yield.

ALUMINUM FOIL MILL — EFFICIENT PRODUCTION OF HIGH-QUALITY, LOW-COST FOIL

The most advanced foil rolling mills in the world enable producers to achieve the highest quality foil at the lowest cost.

The increasing demand for ever higher quality and greater quantities of rolled aluminium foil has forced equipment manufacturers to adapt to new market requirements. 6 micron and below finished thicknesses are now the norm, along with rolling speeds of 2,000 m/min. Primetals Technologies has developed solutions that meet these demands; our mills are state-of-the-art, including features for high-speed operation and control, providing consistant production volumes. Our process know how and support ensures record start-up times with saleable coils produced from cold starts.

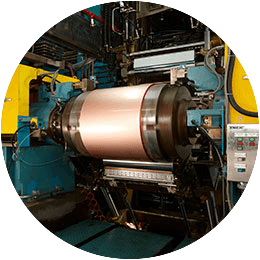

COPPER/COPPER ALLOY COLD AND FOIL ROLLING MILL

The most advanced copper and copper alloy rolling mills in the world enable producers to achieve the highest quality and quantities.

Primetals Technologies offers solutions that satisfy increasing market demand for and trends toward rolled copper and copper alloy sheet/foil. The appropriate mill configuration is crucial for meeting various quality, productivity, and characteristic requirements. Primetals Technologies’ extensive portfolio includes the cluster type mill (6/10-high, 12-high, 20-high), 4-high conventional mill, and 6-high Universal Crown Control Mill (UC-MILL), meeting any customer requirement, and enabling the effective production of high-quality sheet/foil to tight tolerance requirements.