BEAM-BLANK CASTING — REDUCED ENERGY CONSUMPTION WITH NEAR-NET-SHAPE CASTING

Beam-blank casting results in fewer passes in the section mill, reduced energy use and lower production costs.

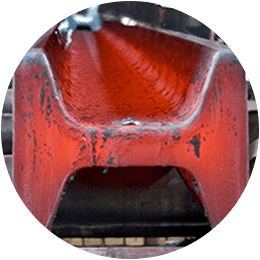

Near-net-shape casting is an energy-saving alternative to conventional bloom casting for the production of beams and sections. The greatest benefits can be derived through the direct coupling of the caster to the rolling mill. The special mold-taper design from Primetals Technologies offers a large operating window with respect to varying casting speeds and different steel grades. High-quality structural beams can be produced with a broad range of product dimensions.

Beam-Blank Casting

In the last years, Primetals Technologies has developed and implemented near-net-shape beam blank casters and special designed combi-caster for long products, which offer the operator highest flexibility with respect to different casting sections and market demands. It is possible to combine the production of billet, bloom and near-net-shape beam blank at one single casting machine. An optimization for beam blank casting has been reached with latest developments in the equipment design and in the fine tuned mold tapers and spray cooling. Primetals Technologies beam blank casters provide high productivity combined with direct hot charging to the rolling mill. Near net shape beam blank casting is an excellent alternative to the more conventional bloom casting route for the production of small to jumbo H-beams and profile shapes.

Main benefits

- Increase of production and flexibility

- Optimum performance and availability

- Assurance of optimized solutions for unique and specialized requirements

- Maximum system and plant availability at low maintenance costs

Want to know more? Go to Integrated Plants & Solutions

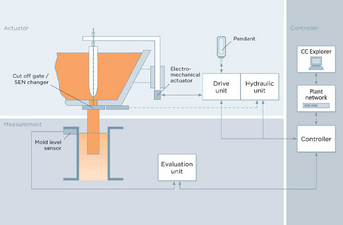

Electrics and automation for continuous casting

Sophisticated automation packages are prerequisite for state-of-the-art quality steelmaking. Primetals Technologies has always been a driver of innovation in this area, especially also providing expert technological packages and models that cover all aspects of the continuous casting process.

The well proven LevCon mold level control package adapts reliably and extremely quickly to mold level fluctuations and changing casting conditions. This is made possible by advanced model-based control algorithms that can actually look into the near future to avoid disturbances in the control loop. The intelligent interaction between the advanced software and highly robust mechanical components improves safety and brings plant operators one step closer to fully automatic casting operation.

Further highlighted technological packages and process experts:

- DynaFlex: hydraulic Oscillator for perfect surface quality

- Quality Expert: a milestone in improved quality supervision, quality prediction and control

- Yield Expert: cut length/weight optimization for minimized scrap and optimized yield

- DynaSpeed: advanced secondary cooling solution

- Nozzle Expert: highest accuracy in detecting clogged nozzles and broken hoses

- Speed Expert: optimal casting speed for increased throughput and improved quality

ECO Solutions for beam blank casting — Saving resources, creating value

Please follow the corresponding links to learn more about our competences:

Gas Cleaning

ECO Consulting

TECHNOLOGY AND MODERNIZATION PACKAGES

Get striking results with incremental investments

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|

| Name | Short Description |

|---|