COLD-ROLLING MILLS

Complete solutions and support packages for cold-rolling mills.

A state-of-the-art cold-rolling mill is essential to the production of steel strip that satisfies the tightest tolerance demands at high productivity levels – for carbon, stainless, and special steel grades such as AHSS (advanced high-strength steel). Thanks to decades of experience in the supply of cold-rolling mills, combined with continuous technological innovation, Primetals Technologies is able to offer fully optimized mill configurations that meet the specific requirements of each customer.

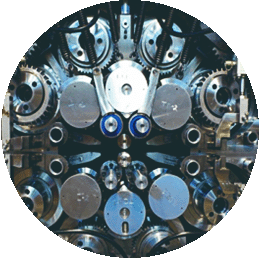

TANDEM COLD MILL

Efficiency and quality production of advanced steel grades.

The Tandem Cold Mill consists of three to six mill stands arranged in series to progressively and effectively reduce the thickness of the strip in a single pass. With its powerful reduction and highest production rates, the Tandem Cold Mill helps steel producers to meet the growing demand for advanced steel grades by enabling high-capacity production. The advanced features of Primetals Technologies’ Tandem Cold Mill with UC-MILL principle help to improve yield and achieve uncompromising quality of strip to meet strict tolerance requirements, while keeping operation simple and user-friendly.

COUPLED PICKLING LINE & TANDEM COLD MILL

Achieves high-capacity production of high-quality products.

For a wide range of product applications, the required strip thickness, flatness, and surface quality can be achieved more economically by linking the pickling and cold-rolling processes. This offers significant improvements with respect to mill productivity, overall yield, and production cost savings as a result of the elimination of strip-threading and tailing-out operations. Speed-optimization systems from Primetals Technologies ensure the highest throughput rates under all operating conditions. In addition, maintenance, roll consumption, and manpower requirements are lowered. Typical production capacities of this type of combined facility are in the range of 1.2–2 million t/a.

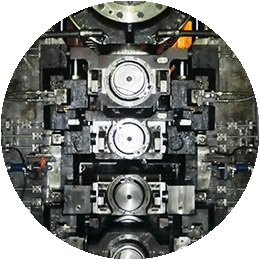

REVERSING COLD MILL

Solution for small to medium-sized production capacities and special steel grades.

In Reversing Cold Mills, the tension reels are placed at both ends of a single or two-mill-stand arrangement. Because the rolling parameters can be quickly changed for each coil, Reversing Cold Mills are ideal for smaller-lot production of various product types, including high-grade silicon steel. The compact size and simple design allow easy access to equipment and machinery for maintenance purposes, and operation can be stopped and restarted more flexibly. The advanced features of Primetals Technologies’ Reversing Cold Mill with UC-MILL principle allow for stable operation and uncompromising quality of strip to meet strict tolerance requirements.

SKIN-PASS MILL

Excellent flatness and a perfect finish.

The advantages of skin-pass mills (temper mills) from Primetals Technologies include full compliance with tight strip elongation tolerances, excellent flatness performance, high surface quality, and the availability of wet and dry skin-passing modes. Primetals Technologies supplies stand-alone and inline skin-pass mills in either single or two-stand design for adjusting the final mechanical properties, flatness, and surface finish of strip. Thanks to its higher flatness control ability, 6-high Universal Crown Control Mill (UC-MILL) is the preferred skin-pass mill solution for meeting the continually increasing demands placed on strip flatness, elongation, and roughness, especially for hard-material grades.

SPECIAL STEEL MILL

Efficient rolling of hard materials.

Special steel mills are specifically designed for the rolling of hard materials such as electrical steel and other special-purpose steels. The various mill designs available include HZ mill, 12-high CR mill, KZR mill (ZR Mill with double AS-U), and 6-high Universal Crown Control Mill (UC-MILL), with small-diameter work rolls for the efficient rolling of thinner and harder materials.

Stainless Rolling Mill

High reduction and excellent finish.

Stainless steel is characterized by high strength and an appealing finish. Various mill designs including KZR mill, HZ mill, and 6-high Universal Crown Control Mill (UC-MILL) with small-diameter work rolls are offered in tandem or single reversing configuration, in order to achieve efficient rolling of hard stainless products. For a smooth and aesthetic finish, Finishing Skin-Pass Mills with large diameter work rolls are integrated into Annealing and Pickling Lines (APL) and are also available as stand-alone reversing machines.