BENEFICIATION & AGGLOMERATION — FROM DIVERSITY OF RAW MATERIALS TO OPTIMIZED PRODUCTS

Intelligent concepts in minerals processing and travelling grate technology with comprehensive metallurgical know-how to design best customized solutions

In view of decreasing availability of high-quality raw materials, the agglomeration of fine and ultra-fine iron ores becomes increasingly important to meet requirements of BF and DR plants. Primetals Technologies’ comprehensive technological expertise on the entire metallurgical process chain is the basis for tailor-made sinter and pellet quality. This know-how also includes an in-depth understanding of the mineralogical properties of the ores which is essential for a wide range of applications – from laboratory testing to large-scale plants. The focus on chemical and metallurgical properties as well as physical product requirements is just as important as the ecological footprint. Energy efficiency, state-of-the-art off-gas cleaning and advanced process control are integrated components of Primetals Technologies technical solutions.

IRON ORE BENEFICIATION — FROM NATURAL RESOURCES TO VALUABLE PRODUCTS

Mineral Processing is the cornerstone of Efficient and Sustainable Steel Production and essential to providing a High-Quality Raw Material for the Metallurgical Production Chain.

As a life-cycle partner in the global iron and steel business, Primetals Technologies offers specialized solutions for iron ore beneficiation, as well as for tailings management and processing. Extensive knowledge of downstream iron and steel production technologies, combined with access to a large network of renowned institutes and universities, means we are uniquely positioned to focus on the entire metallurgical processing route and therefore able to optimize the customer’s entire value chain in terms of Capital Expenditures (CapEx), OPEX, and product quality. Our applications are driven by key factors such as ecological footprint, sustainability, a high degree of automation, and autonomy in the choice of processing equipment.

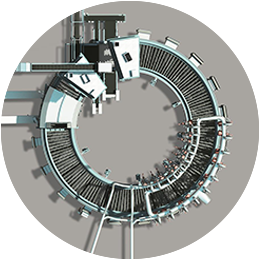

PELLETIZING TECHNOLOGY — PLANTS, REVAMPS, MODERNIZATIONS, AUDITS, STUDIES, AND TEST WORKS

Primetals Technologies offers the full range of pelletizing capacities, from the smaller capacities involving unique Circular Pelletizing Technology (0.5 - 2.0 mtpa) to larger capacities based on straight travelling grate technology (from 1.5 up to 9 mtpa).

To be able to meet customers’ diverse pelletizing requirements, Primetals Technologies developed a comprehensive package of tools based on extensive industry expertise that allows the full spectrum of operational challenges to be met quickly and efficiently – customized to individual needs. The cornerstone of Primetals Technologies' pelletizing solutions is a combination of in-depth practical investigation (on-site plant audits, pot grate test work) and theoretical analyses (plant simulations, process calculations). This enables Primetals Technologies to develop technical concepts for new pelletizing plants, as well as for revamps or performance upgrades of existing plants. Thanks to Primetals Technologies’ solutions, pelletizing plants can be improved with selective measures and debottlenecking initiatives can be implemented, for example through burner management, grain size control, process automation, and emission reduction.

SINTER TECHNOLOGY — HIGH-PERFORMANCE AND ENVIRONMENTALLY FRIENDLY SOLUTIONS

Sinter technology developed by Primetals Technologies ensures high and stable sinter quality for optimized blast furnace operation, a high degree of flexibility of raw materials, and low operating costs.

Requirements for availability, product quality and productivity of sinter plants are continuously growing. At the same time, environmental regulations are becoming increasingly stringent and require innovative solutions. As a full-liner in the metallurgical industry and a leading technology supplier of sinter plants, we strive to create exceptional technical solutions that meet the latest environmental requirements and consider economical aspects. This applies to new plants as well as to modernizations and plant upgrades. With 5 decades of experience, we are proud to be a technology leader in travelling grate solutions.