Arvedi Endless Strip Production (ESP) offers all options in green steelmaking

From commodity to advanced grades, from narrow to wide, from ultra-thin to thick

Endless hot rolled coils (eHRC) from commodity to advanced grades

Arvedi Endless Strip Production (ESP) offers you everything from commodity and commercial segments to the most sophisticated applications. eHRC products are found in all steel grade families, from high formability to high strength. The ESP proves to be the perfect transition technology to change from hot strip mill product mixes to endless production.

Request paper download: Zero-carbon-emission hot rolling of direct application sheet with real ESP

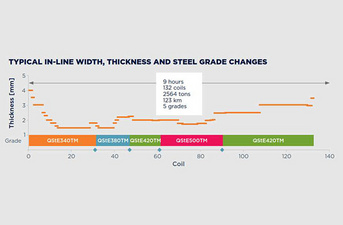

Steel grade, width, and gauge change

During operation, Arvedi Endless Strip Production (ESP) offers you the following flexible options:

- Steel grade changes are handled fully automated in the tundish. Level 2 support is given by the Intermix Expert model.

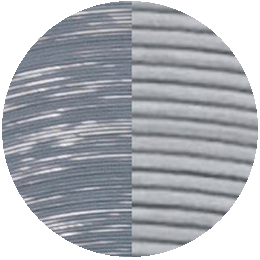

- The width is controlled directly in the mold with the reliable DynaWidth hydraulic taper and width control. The stable conditions of endless rolling are crucial to the highest width accuracy.

- Thickness is controlled throughout the sequence by patented flying gauge changes, which omit off-gauge production during thickness changes in endless mode.

Request paper download: Arvedi ESP proofs its flexibility at Rizhao Steel

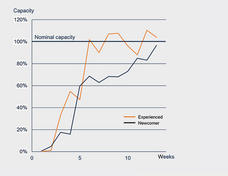

Inline work roll change in hot rolling mill

Inline work roll change in the last finishing stands during ongoing hot rolling allows the highest sequence lengths without needing to hold a buffer, just as CO2-emitting tunnel furnaces do.

Request paper download: Arvedi ESP proofs its flexibility at Rizhao Steel

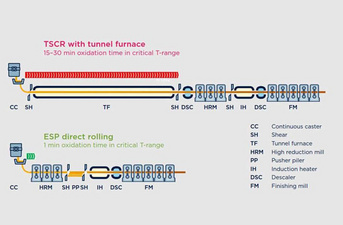

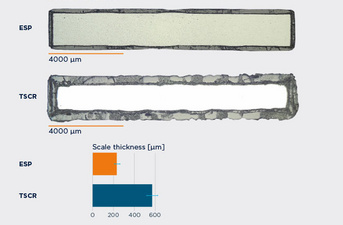

Higher copper tolerance on scrap-based Electric Arc Furnace (EAF) routes

Due to its compact design, Endless Strip Production (ESP) can perfectly cope with higher amounts of tramp elements (such as copper) in a scrap-based EAF production since there is little time for copper enrichment on the surface (no tunnel furnace) before the first rolling step. The steel on the Arvedi ESP line stays in the critical temperature range for selective oxidation for only 1 minute, while on tunnel furnace TSCR, it takes 15 to 30 minutes.