Automotive quality requirements and process adaptations for continuous galvanizing lines

Practical training

This three-day customizable course provides a detailed insight into the process-technological aspects of the production of galvanized products (coils).

Course description

The main focus is on surface quality, root causes, and requirements for automotive exposed production. The training venue is typically near the customer's plant in order to ensure joint plant observation and take into account the actual plant situation, and to be able to carry out valuable production analyses and make appropriate recommendations.

Emphasis is placed on the influence of incoming material, process parameters, and operational practice on product quality.

Basic information about management, organization, maintenance, and production planning is explained, insofar as it influences product quality.

Target group

Process operators, foreman, process engineers, quality engineers, technologists, line managers from galvanizing lines, and researchers

Course outline

- Management and organization of processing lines

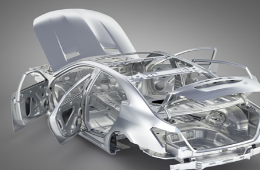

- Theory and basics of coated steel sheet for exposed application

- Snout operation and decrease of zinc dust and dross formation

- Pot management and dross control

- Air knife operation and wiping defects

- Submerged roll maintenance and operation

- Production scheduling, pre-conditions and standard operating practice for automotive exposed production (O5)

- Release standard and non-permissible surface defects

Contact us and register for training