CONVERTER STAINLESS STEELMAKING — INCREASED EFFICIENCY WITH SOLUTIONS FROM THE WORLD MARKET LEADER

Primetals Technologies supplies the entire chain of stainless steel production technologies – from scrap preparation to the finished product. Our expertise as the world leader in stainless steelmaking technology supports producers to boost their productivity and performance.

The demand for stainless steel increases each year, as well as the price pressure. Accordingly, plant operators must invest in process optimization and expand capacity to remain competitive on an international basis. Primetals Technologies offers its customers optimized solutions for increased productivity, improved plant availability, and full compliance with environmental regulations.

CONVERTER STAINLESS STEELMAKING

For special requirements like high corrosion resistance, high temperature resistance or highest strength stainless steels have been developed. These steels are characterized by high amount of alloying elements, most important Chromium and Nickel. Typically such steels are made from stainless steel scrap which is melted in an Electric-Arc-Furnace and then processed in an Argon-Oxygen-Decarburization converter before final adjustment of temperature and chemistry of the heat is done in a Vacuum-Oxygen-Degassing station. Beside such scrap based stainless steel production hot metal and pig iron rich in Nickel are successfully used in several plants worldwide. Developing the cost optimal process route for the actual raw material base is one of the core competencies of Primetals Technologies.

Core aggregate for all production routes is the AOD converter which allows very efficient removal of Silicon and Carbon while minimizing the losses for Chromium. Majority of the total worldwide installed AOD capacity was supplied by Primetals Technologies. One reason for our market leading position in this area is our strong link between process, mechanic and automation as well as our continuous developments for further improvements of the process and the equipment. Highlights of these developments are damper to reduce vibrations during the blowing process, single shroud control for longest lifetime of the tuyeres, Vaicon Quick vessel suspension system for fastest vessel exchange, scrap charging machine or sublance for temperature measurement and sample taking.

Additionally Primetals Technologies has a wide portfolio of special converters.

Want to know more? Go to Integrated Plants & Solutions

Intelligent automation for steelmaking

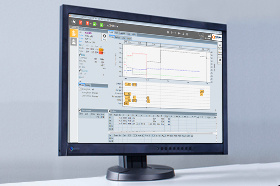

As a supplier of comprehensive solutions for the entire steel production route, Primetals Technologies provides automation systems for stainless steel converters covering the complete range of available refining technologies, such as AOD and K-OBM-S. Our automation solutions focus on ensuring an optimum metallurgical and process technological performance with respect to steel quality and operational costs.

Intelligent control of the converter process is performed by the application of Steel Expert - a comprehensive suite of metallurgical models. Our process optimization models increase the productivity and lead to improved and assured steel quality. The consumption of process gases and reduction agents is optimized and the refractory costs decrease.

To assure top quality stainless steel production, Steel Expert Prediction simulates the complete AOD process before the heat is actually started, using various setpoint models. Steel Expert Charging calculates a cost-optimized mixture of pre-melt portions.

During the process full control of process steps (e.g. decarburization, desulphurization, reduction) is provided and the Steel Expert Supervision dynamically calculates the current state of steel and slag throughout the stainless steelmaking process. Thus the temperature, weight and chemical analysis of steel can accurately be adapted to the planned steel quality.

Further highlighted technological packages:

• Equipment Position Manager: automatic electronic tracking of metallurgical vessels at treatment stations

• Lance Checker: closed loop test system for all types of temperature and sample taking lances

ECO Solutions for converter stainless steelmaking — Saving resources, creating value

Please follow the corresponding links to learn more about our competences.

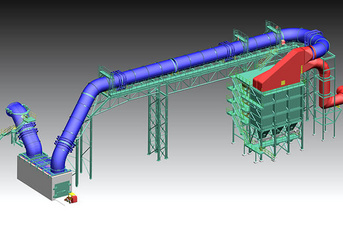

Gas Cleaning

Energy Efficiency

By-Product Recycling

Water Treatment

ECO Consulting

TECHNOLOGY AND MODERNIZATION PACKAGES

Get striking results with incremental investments

| Name | Short Description |

|---|---|

| Lance Checker | Test and diagnosis system for liquid iron and steel measuring devices |

| Leakage Monitor | Leakage detection system for water cooling circuits |

| Bag Filter Controller | Smart control of bag filter cleaning for dedusting plants |

| Equipment Position Monitor | Reliable identification and tracking of metallurgical equipment throughout the steel plant |

| Bag Cleaning Monitor | Acoustic monitoring of pulse jet bag filter plants |

| Discharge Monitor | Acoustic monitoring of truck or wagon discharging |

| Grain Size Monitor | Acoustic measurement of material grain size on conveyor belts |

| Automatic Gas Coupling | Automatic gas coupling for ladle stirring |

| Scrap Composition Monitor | Automatic identification of unwanted or dangerous ingredients in the scrap |

| Scrap Profile Monitor | Fully automated 3D profile and volume measurement system for scrap piles |

| Freeboard Monitor | Online measurement system for ladle freeboard during tapping |

| Material Type Monitor | Automatic identification of the type of material on conveyor belts |

| SlagMon | Reliable slag detection for optimized tapping |

| Lomas | Gas analysis system for very hot corrosive and dust-loaded process gases |

| BOF Tapping Expert | Safe tapping for all types of steelmaking converters - LD (BOF), AOD and KOBM |

| LF / RH /VD Optimizer | Dynamic Process Optimization (Level 2) for Secondary Metallurgy (LF/RH/VD) |

| AOD Optimizer | Dynamic process optimization (Level 2) for stainless and special steelmaking |

| LiquiRob for Steelmaking | Robotic solution for EAF, BOF, ladle furnace, VD |