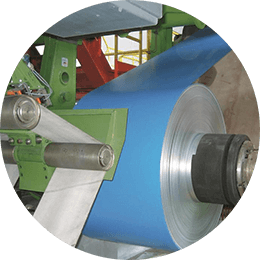

ORGANIC COATING LINES — COLORFUL PRODUCTS FOR CORROSION-PROTECTION APPLICATIONS

Continuous Coating Lines offer high throughput rates, reliability, and flexibility, and provide the basis for outstanding strip-coating quality.

Primetals Technologies offers a full spectrum of solutions to meet the requirements for a wide range of product applications. The strictest demands for high-end applications are fully met, such as in the automotive and household appliance industries. Both primary and secondary organic coating layers can be imparted to both sides of the strip.

ORGANIC COATING LINES

Based on decades of experience in the engineering, supply, installation, and start-up of organic coating lines, Primetals Technologies offers optimized solutions for different coating compositions, coating colors, various steel grades, and varying strip dimensions. In addition to imparting an aesthetically pleasing and decorative appearance to the strip, color coatings substantially improve corrosion resistance, especially for outside use. The key coating process machines are the roll coaters, which are in-house mechatronics equipment.

Roll coaters

Our coaters include all technological aspects, including mechanical, fluid, electrical, and automation functions. This modular approach offers considerable benefits and allows us to provide completely integrated solutions consisting of extensively preconfigured products, solutions, and cycle services specifically tailored to your needs. The main benefits of our coaters are: fewer vibrations due to short universal joints, less applicator roll covering wear due to load control, quick roll change, reduction of coating consumption, tightest thickness tolerances based on dynamic force control, and quality improvement thanks to computer-controlled coater presetting.

Features

- Stitcher

- Optimized pretreatment

- Application of coater control

- Special oven design

- Fully automated line presetting and program change

- Tension Leveler to improve strip surface quality

- Integrated environmental solutions

Main Benefits

- Ideal coating adhesion

- Uniform coating thickness with low coating-media lacquer consumption

- Fast and homogeneous heat transfer to the strip

- Increased yield and throughput capacity

Want to know more? Go to Lifecycle Services & Integrated Plants & Solutions

TECHNOLOGY AND MODERNIZATION PACKAGES

Get striking results with incremental investments

| Name | Short Description |

|---|---|

| EdgeMon | Inspection of side-trimmed strip edge surface for steel pickling and processing lines and aluminum rolling |