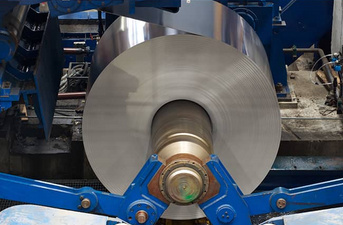

ALUMINUM HOT ROLLING MILL — HIGH-QUALITY PRODUCT & MAXIMUM MATERIAL YIELD

Primetals Technologies provides a full range of aluminum hot rolling mills for both new and revamp projects.

As the demand for higher quality and greater quantities of rolled aluminum increases, so do demands on production equipment. Primetals Technologies' solution offers a combination of mechanical actuators, electrical and automation control systems, and applied process know-how to deliver gauge, profile/flatness, temperature, and surface quality with the highest level of consistency. With our flexible mill configuration, high-quality strip can be rolled in capacities between 100,000 to 1,000,000 tonnes per annum.

Aluminum Hot Rolling Mills - Advanced technology for high-quality products

Primetals Technologies' aluminum hot rolling mill portfolio and experience comprises:

- Single and Two-Stand Roughing Mills

- Twin Coiler Reversing Mills

- Tandem Finishing Mills (three, four, and five stands)

- Mini Mills (integrating caster with Tandem Finishing Mill)

- Plate Mills

To meet the needs of the aluminum market, our hot mill solutions feature a range of common technological enhancements to increase performance, operability, safety, and surface quality. These include:

- SmartCrown roll contour, which guarantees enhanced profile and flatness control

- Heavy work roll bending for improved profile control

- Integral Solenoid Valve (ISV) spray system for improved profile and flatness control

- Interstand strip cooling for improved finishing mill throughput

- Edge trimmer delivers improved yield and reduces cold mill strip breaks

- EdgeMon for improved strip edge quality

- Roll gap sensor for improved profile control and throughput

- Mill Stabalization Device (MSD) for reduced cobbles and improved mill availability

- Variable angle roller tables for optimum bottom surface quality

- Rapid, side shifting work roll change for improved mill availability

- Fully hydraulic vertical edger for improved yield

- Hydraulic shears for improved mill availability

- Automatic coil welder for enhanced operator safety

- Remote belt tracking on the wrapper for operator safety

- Pressure plate filter (Schneider) for improved surface quality

Want to know more? Go to Lifecycle Services & Integrated Plants & Solutions

Complete automation and process control for Aluminum Hot Rolling Mills

Plant productivity and product quality are governed to a large extent by the quality of plant automation, process control, and available process optimization functions. Primetals Technologies delivers standardized, high-performance automation systems that seamlessly integrate:

- Digitalization packages (e.g. TPO, MAT, Condition Monitoring, Intelligent Sensors)

- Production management systems (Level 3)

- Physical models combined with artificial intelligence (Level 2)

- Automation solutions, including advanced technological controls (Level 1)

For existing installations optimization packages are available as standalone solutions designed to improve production efficiency and strip quality.

Throughput maximization with:

- Comprehensive Temperature Model and Control (CTM and CTC)

- Mill Pacing

Excellent strip quality with:

- Contour and Flatness Optimizer

- Model-based roll alignment control

- Periodic Disturbance Compensator

- Coil Eccentricity Expert

Our solutions encompass:

- Process Automation Twin for safely developing new materials and optimizing rolling schedules

- Schedule free rolling (“Lot 1 production”)

- Central Operation Cockpit to support mill operation (centralized operation)

- Software architecture open for customers' own future developments

- Modular structure for step-by-step modernizations

TECHNOLOGY AND MODERNIZATION PACKAGES

Get striking results with incremental investments

| Name | Short Description |

|---|---|

| Integrated Solenoid Valve (ISV) Spray System | ISV Roll coolant spray bars for hot and cold rolling mill strip flatness control |

| Roll Eccentricity Expert | Elimination of a known strip thickness quality disturbance from rolls |

| Modular Coil Shuttle System (MCS) | Rail-based, fully automated modular coil transport system |

| Coil Eccentricity Expert | Elimination of a known strip quality disturbance |

| TorqueMon | Inline measurement of roll spindle torque for rolling mills |

| Position Transducer | Position measurement of rolling mill hydraulic capsule |

| EdgeMon | Inspection of side-trimmed strip edge surface for steel pickling and processing lines and aluminum rolling |

| Schneider® Filter | Coolant Filtration System for rolling mills |