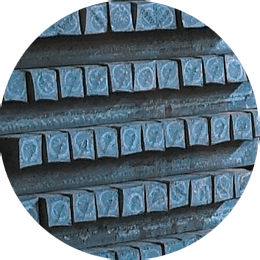

STATE-OF-THE-ART SOLUTIONS FOR WIRE ROD AND BAR MILLS

Primetals Technologies has a complete portfolio of solutions for wire rod, bar, and non-ferrous mills. Deep knowledge that draws on more than 150 years of history from the tradition-rich brands of Morgan and Ashlow. Primetals Technologies has a record of more than 500 plants installed, and continues with ongoing innovation with hundreds of active industrial patents.

Today's demands for flexible and economic production of long products can only be met by production process, electrical and automation solutions that are based on precise process modeling, high-performance control systems and in-depth understanding of long product rolling technology. Drawing on more than a century of experience and proven solutions, Primetals Technologies has the answers to complex and diverse market demands – from the smallest upgrade to the greatest technical challenges for high-speed and special steel grade products. With our world-class equipment, processes and design tools, we set benchmarks for rolling long products. We offer worldwide proven and extensively preconfigured solutions, including modular standard packages as well as global and intelligent service concepts for the entire equipment lifecycle.