DIRECT LINKED CASTING AND ROLLING PLANTS

A new generation of future-oriented casting-rolling complexes.

The direct linking of casting and rolling processes is an essential factor to minimize energy consumption in rolling, improve product consistency, and maximize yield. Primetals Technologies has direct linked casting and rolling solutions for both flat and long products.

ARVEDI ESP — REAL ENDLESS STRIP PRODUCTION

The trailblazing endless strip production technology offers the promise of revolutionizing flat-steel production in the same way that LD converter steelmaking technology and continuous casting changed the face of the steelmaking industry in the previous century. A wide range of high-quality and ultra-thin steel grades can be produced with the endless cast-rolling process.

The Arvedi ESP process produces hot strip in a combined, continuous and uninterrupted casting and rolling process. In this type of plant, the energy consumption and the associated costs are up to 45 percent lower than those of conventional casting and rolling processes. This also means a significant reduction of CO2 emissions. With a length of just 180 meters, the plants also have considerably more compact dimensions than conventional casting and rolling mills. A wide range of high-quality and ultra-thin steel grades can be produced with the endless cast-rolling process.

Castrip® Technology

Efficient and high-quality flat steel production with innovative twin-roll casting and rolling

The Castrip process is a revolutionary method for producing flat rolled carbon and silicon-steel sheets at very thin thicknesses. Castrip technology allows steel makers to produce thin flat rolled products in significantly fewer process stages, saving money on both initial investment and operating costs. By casting steel close to its final dimensions, enormous savings in time and energy can be realized.

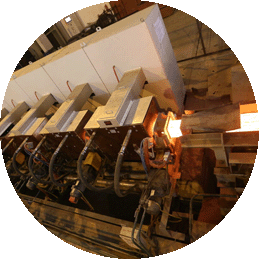

ENDLESS BAR PRODUCTION

Cutting Conversion Costs for Long Products

The Endless Bar Production (EBP) merges a billet caster and high-speed mill, running continuously without reheating between casting and rolling. It slashes energy use by 60% and CO2 emissions by over 90% compared to conventional methods. With minimal material losses, it achieves a remarkable 99% yield. Conversion costs are 40% lower on average, thanks to reduced inventory and infrastructure. Endless Bar Production, born from Arvedi ESP technology, boasts top-tier performance, reliability, and eco-friendliness.