PROCESS & TECHNOLOGY CONSULTING

Profit from our integrated process know-how and global presence!

Process & technology consulting to increase plant performance and reduce conversion cost to support quick and proper selection of feasible improvement measures: Primetals Technologies offers technology consulting services which help producers to achieve and maintain high standards in production excellence. On the basis of decades of experience in the engineering, installation, start-up and commissioning of steelmaking plants worldwide, our specialists are skilled in identifying potentials for improving plant performance in the course of a performance checks. Detailed and individual concepts are proposed to optimize a process, equipment and quality from raw material to different steel types. By implementing these measures steel producers can ensure permanent production excellence of their plant on a cost-effective basis.

Optimization of integrated processes & steel works

Increase your efficiency and profitability with our range of tools, which provide support for quality control, optimization for cost, profit, and CO2 emissions through simulation platforms.

Technical assistence with Through-Process Optimization

Our experienced instructors aim to provide your teams with comprehensive technical support in the area of quality control in your steel works. We provide training, documentation, and assistance to bring you process know-how, coordinated management from steelworks to processing lines, and an accelerated return on investment, in order to increase your efficiency and profitability.

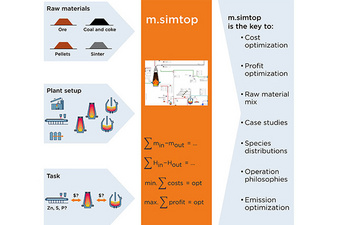

Simulate & optimize with m.simtop

Drawing on extensive experience in novel process concepts, cost investigations, and material distribution tracking, our simulation tool m.simtop optimizes mass and energy balances. With 20 process models, over 250 sub-models, and integrated thermodynamic routines, it's ideal for single plants or complex steelworks. Emulating a steel plant's business environment, m.simtop refines strategic planning and operations through scenario analysis. Its metallurgical model library enables efficient holistic plant modeling and instant result generation.

Benefits

- Strategic and holistic operational planning, process optimization, and strategic planning scenarios as a basis for management decisions

- Calculations of asset scope and given setup of steel works, material balances, impact of raw materials, energy flows

- Calculation and optimization of cost, emissions, and KPIs through variation of raw material blends and adjustable process parameters

- Configuration of optimization routines based on individual customer demands

- Simulation of the effects of a plant undergoing maintenance

- Evaluation of the impact of different operational philosophies or recycle loops within an existing process

Want to know more? Watch the On-Demand Webinar CO2 Emission and Cost Optimization of Steelworks.

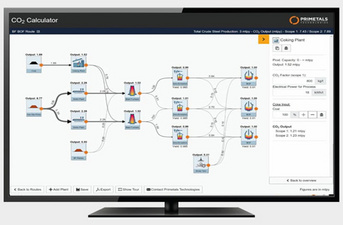

Determine your emissions with the CO2 calculator

On the self-explanatory interface, users can input almost any steel production route, subsequently tweak this to indicate any potential changes to CO2 emissions, compare a production route to common standard routes, and discover optimization approaches. The CO2 Calculator features an interactive tour for new users that starts automatically at the first log in and can be easily revisited by clicking the “Show Tour“ button. All routes calculated can be saved for later use and it is also possible to export a .pdf file with a route summary, free of charge. Find out more

Click here to determine a production route’s carbon emissions.

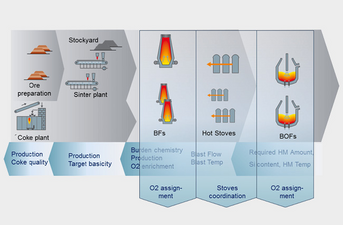

IMTC — Ironmaking Technologies Consulting

Expert Assistance for Improved Performance and Operations

As quality and productivity requirements in ironmaking technologies are continually increasing, producers must respond and adapt in order to remain competitive. Expert advice from a highly experienced supplier of ironmaking technologies maximizes the performance of your plants.

Our expertise covers all aspects from ironmaking technologies as sintering, pelletizing, hot metal production with blast furnace and/or COREX®, sponge iron production with direct reduction technologies. Primetals Technologies are able to provide comprehensive training and advice on improvements in productivity, process stability, and stable product quality under varying quality demands from steel making plants, achieving a fast return on investment.

An initial ironmaking fitness check by visual inspection, detailed investigation and study culminates in presentation and discussion of results and proposals for improvements, including costs and benefits. Quality improvements are achieved by metallurgical investigations, by back/forward calculations considering chemical and thermodynamically behavior of input materials and required output chemistry. By that way of mass – and energy balancing the finally minimum energy input is maintained.

Primetals Technologies are able to optimally support many aspects of your ironmaking operations:

- Optimized production meeting requirements of respective downstream plants

- Cross plant coordination for optimal gas network utilization

- Transparent and traceable production decisions

- Reduction of costs and increase of production

Steelmaking technology consulting

Expert assistance for performance improvement in steelmaking

As quality and productivity requirements in steelmaking are continually increasing, producers must respond and adapt in order to remain competitive. With greater need for raw material flexibility and energy savings expert advice from a highly experienced supplier of steelmaking technology maximizes the performance of your plant. Primetals Technologies, a steelmaking technology supplier with decades of experience in engineering, installation, start-up and commissioning, are able to improve plant performance, reliability and safety. This is achieved by optimizing the process, equipment and quality from raw materials to liquid steel to provide permanent production excellence on a cost effective basis.

Our expertise, covers converter and electric steelmaking technologies for LD (BOF), AOD and EAF and secondary metallurgy with VD, VOD and RH technologies. As well as providing immediate support and over 50 Steelmaking Technology Consulting references, Primetals Technologies have an efficient 3 step consulting methodology which can identify improvement potential leading to cost savings and improved production quality with a fast return on investment.

The first step by our experts is a performance check including evaluation of the equipment, discussions with your experts and culminating in a report and expert comment. The second step is an evaluation of detailed concepts and expert discussion which is finalised with a presentation of the results and measures for a solution. This includes expected costs, benefits and time schedule for subsequent implementation. In the third step implementation of these measures is carried out in a fast and professional way by our experts to ensure optimal results which are further supported by comprehensive training for operators and metallurgists.

Productivity can be improved by process benchmarking, logistics studies and energy efficiency and environmental protection. An equipment evaluation helps you to profit from our engineering experience providing life-time prediction, future requirements and opportunity for customized upgrades. Finally, excellence in steel quality can be achieved through metallurgical, energy and environmental investigations, logistical studies and technological training. All provided by a team of experts in steelmaking technology.

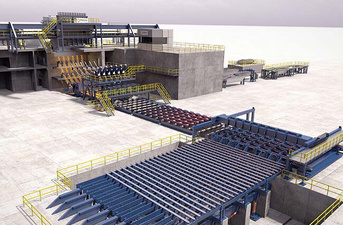

Caster Technology Consulting (CTC)

Expert Assistance For Improved Performance

As quality and productivity requirements in continuous casting are continually increasing, producers must respond and adapt in order to remain competitive. Expert advice from a highly experienced supplier of continuous casting technology maximizes the performance of your plant. Primetals Technologies, a world leading supplier of continuous casting technology with decades of experience in engineering, installation, start-up and commissioning, are able to improve plant performance, reliability and safety.

Our expertise, covers all aspects of continuous casting technology for billet, bloom, beam-blank and slab casters from any supplier. As well as immediate support and over 160 Caster Technology Consulting references Primetals Technologies are able to provide comprehensive training and advice on improvements in productivity, process stability, product quality and yield, achieving a fast return on investment.

An initial caster fitness check and a detailed investigation and study, culminates in presentation and discussion of the results and proposals for improvements, including the costs and benefits. Quality improvements are achieved by metallurgical investigations, optimization of both surface and internal quality as well as automation set-up, further supported by technological training. Our “Tools to See Inside the Strand”, such as Computational Fluid Dynamics and Thermomechanical and Equipment Quality Simulations achieve the highest level of quality in the shortest possible time. Onsite analysis of equipment identifies potential weaknesses and proposals for quick and cost effective solutions. Primetals Technologies are able to optimally support all aspects of your continuous caster operations.

Technology consulting rolling mills and processing lines

Rolling mill and processing lines have a lifetime of several decades. During this time, mills and lines must be kept in the condition to meet market demands for a wide range of steel grades especially and extension to new grades, quality requirements or dimensions. At the same time high yield, mill availability and production throughput have to regularly pushed to achieve the competitive level to ensure also economic success.

Primetals Technologies use a systematic approach working closely with our customers to develop a tailored upgrade, modernization or extension concept according to the particular requirements. Prior to such investment steps Primetals Technologies may offer specific investigations (studies) in order to e.g. check technical feasibilities, to identify bottlenecks or justify investment estimations.

Primetals Technologies plant building experience, feedback from installed references and application of dimensioning and simulation tools guarantee that the results of such studies are of the highest standard of technical elaborations.

Beside high-tech equipment and skilled employees a comprehensive process know-how and metallurgical know-how is necessary for the successful operation of a rolling mills as well galvanizing and annealing lines. Primetals Technologies support customers with metallurgical simulations for further development of steel grades or introduction of new grades.

Typical study procedure

Data Colletion

- Definition of goal

- Validation of current situation

- Define target situation from a process engineering perspective

Analysis & Benchmarking

- Analysis of technical feasibility

- Bottleneck analysis

- Hidden potentials

Results

- Specification of measures

- Evaluation of shutdown planning and cost estimation

- Presentation of study

- Technology packages

Electrics and Automation Consulting

In order to match our customers needs to lower conversion and raw material costs respectively improve plant performance and product quality at the same time, innovative answers are always in close connection with electrics&automation solutions. Primetals‘ senior automation experts are at disposal to evaluate the actual status of installed automation systems as well as all process relevant areas such as drives, power distribution and instrumentation. The findings of such plant assessments will be documented in detailed reports including recommendations for improvements.

Tailor-made composed packages are available for topics of:

- Operational consulting

- Benchmarking

- Operation improvements

- Feasibility studies

- Logistics

- Preventive maintenance studies

- Optimization of electric power supplies

- Energy management value scan

- Plant assessment

- Condition analyses

- Energy consumption

- Plant performance

Eco Consulting

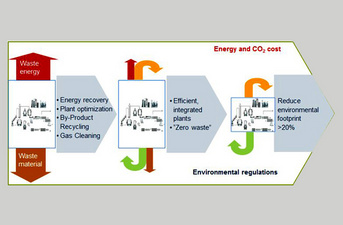

Compliance of steelmaking processes with environmental standards has become a key challenge of our times. Primetals Technologies has the competence and experience to fulfill environmental standards and to help producers saving resources and creating value at every step of the metals production chain. Especially environmental consulting can be provided for gas cleaning (emission reduction), waste heat recovery systems (energy efficiency increase) and by-product utilization (recycling).

Saving resources:

- Optimized use of raw materials

- Minimized gas emissions

- Reduced energy consumption

- Significant reduction in particulate and gaseous emissions

- Efficient by-product treatment and recycling

Creating value:

- Improved plant performance

- Lower conversion costs

- Reduced environmental taxes and disposal costs

- Increased energy recovery

- Substantially improved working conditions and safety

By means of our three step ECO consulting approach industrial “loops” are closed (“zero waste”) and producers profit from an increased plant performance while ensuring strict adherence to environmental regulations.