News & Press Releases

-

London, April 24, 2024

Primetals Technologies’ Modernization of Slab Sizing Press to Boost Reliability for Salzgitter Flachstahl

Salzgitter Flachstahl, a subsidiary of the Salzgitter Group, has tasked Primetals Technologies with a comprehensive upgrade of its power and electrical system for the slab sizing press in its hot-rolling mill in Salzgitter, Germany. The modernization will ensure increased availability and a future-proofed supply of spare parts.

more

-

London, April 22, 2024

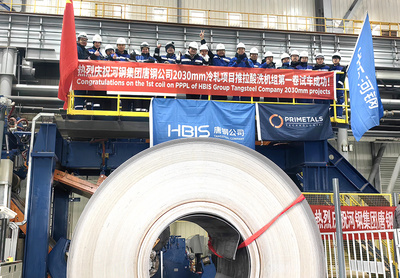

World’s Largest Push-Pull Pickling Line Produces First Coil at Tangsteel, China

Primetals Technologies has recently implemented the world’s largest push-pull pickling line (PPPL) at Chinese steel producer HBIS Tangsteel’s steel plant in Laoting, Hebei province, China. The core aim of Primetals Technologies’ push-pull pickling line is to enable an extraordinarily wide product range in terms of strip dimension, steel grade properties, and production capacity.

more

-

London, April 18, 2024

Zhongshou Special Steel Group Chooses Arvedi ESP for Transition to Green Steel Production

Chinese steel producer Zhongshou Special Steel Group has ordered an Arvedi ESP line from Primetals Technologies for its plant in Luanzhou, Hebei Province. A proven high quality of hot-rolled coil produced in endless mode as well as the absence of fossil fuel consumption where the main reasons behind Zhongshou’s choice of technology.

more

-

London, April 10, 2024

Rizhao Steel to Benefit from Fully Automated Plant with Innovative Solutions from Primetals Technologies

Rizhao Steel has placed an order with Primetals Technologies to implement advanced process automation systems and technological packages at its integrated steel plant in Rizhao, China. Powerful metallurgical models, dynamic process control systems, and detailed calculations of input materials will enable full plant automation, “one-button steelmaking”, from a central control station.

more

-

London, April 03, 2024

New Robotics Concept for Safer Casting Operations Realized at Steel Producer in Thailand

Thai steel producer Siam Yamato Steel has realized a new robotic concept from Primetals Technologies, including LiquiRob, at its steel plant in Map Ta Phut. Thanks to the robotics solution, safety and occupational health have improved significantly at the steel plant.

more